Post-show report from the 2024 International Welding Show

Table of contents [hidden]

- 1.Visit a welding show

- 1.1.Thankyou for visiting our exhibit

- 1.2.Ourfeatured products

- 1.3.Demonstrationof automatic pipe welding

Visiting the welding show

Thank you for visiting our exhibition.

We exhibited at the 2024 International Welding Show, held at INTEX Osaka from Wednesday, April 24th to Saturday, April 27th, 2024.

The International Welding Show was held in Osaka for the first time in eight years. A record 340 companies exhibited, and a total of 100,307 people visited the show.

We would like to express our sincere gratitude to the many visitors who stopped by our booth over the four days of the event.

Our featured products

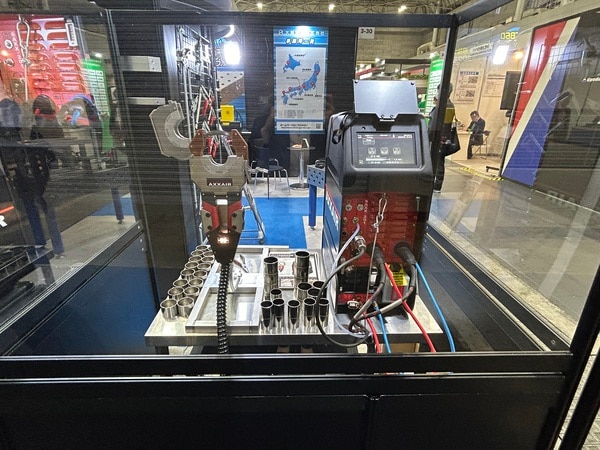

The highlight of our company is AXXAIR's automatic pipe welding device "SAXX-201".

SAXX-201 can automatically and easily weld thin-walled pipes, which are difficult to weld.

After setting the pipe on the closed welding head, input the diameter and pipe thickness into the touch panel and the welding conditions will be automatically called up. Simply press start on the touch panel to begin welding.

In addition, the worker's smartphone and the welding power source can be linked via Wi-Fi, enabling remote operation.

SAXX-201

Welding can be completed by simply setting the pipe.

Automatic pipe welding demonstration

The International Welding Show is an attractive exhibition. Each booth had a different vibrancy to it than a typical sales-type exhibition.

We also demonstrated automatic pipe welding using the SAXX-201 at our booth.

I think that everyone was able to see everything from setting the pipes to calling up the welding conditions, welding, remote control with a smartphone, and the beautiful appearance of the workpiece after welding. We were very pleased that many people stopped by our booth where we were demonstrating.

Pipe welded with SAXX-201. It has a very beautiful bead.

The SAXX-201's compact welding head makes it effective for working in tight spaces and at high altitudes, and it is useful for piping welding in semiconductor, pharmaceutical, beverage, food factories, power plants, and other facilities.

We will strive to further expand sales in the future and make proposals that will contribute to our customers' business improvement and labor saving.