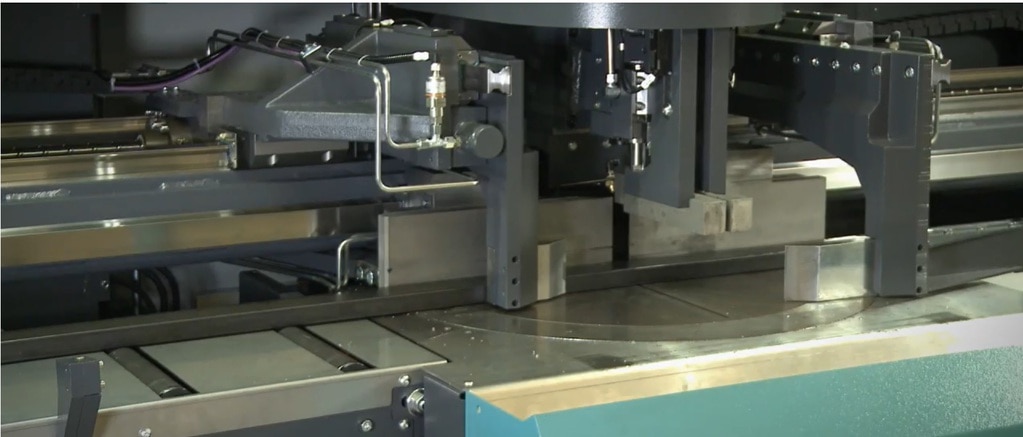

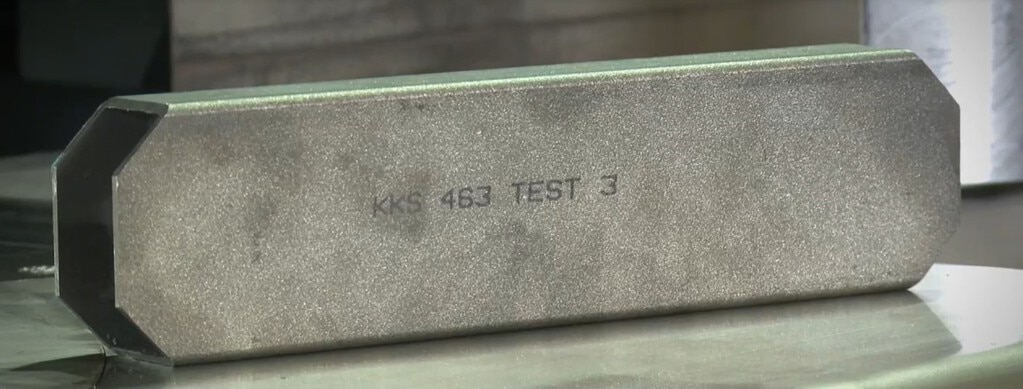

Revolutionize cutting accuracy and efficiency with KKS463!

With quick response

We respond to your requests

Nikko Co., Ltd.

Director Keiichi Katsuyama

Mr. Yasuhiro Ozawa, Logistics Section Manager

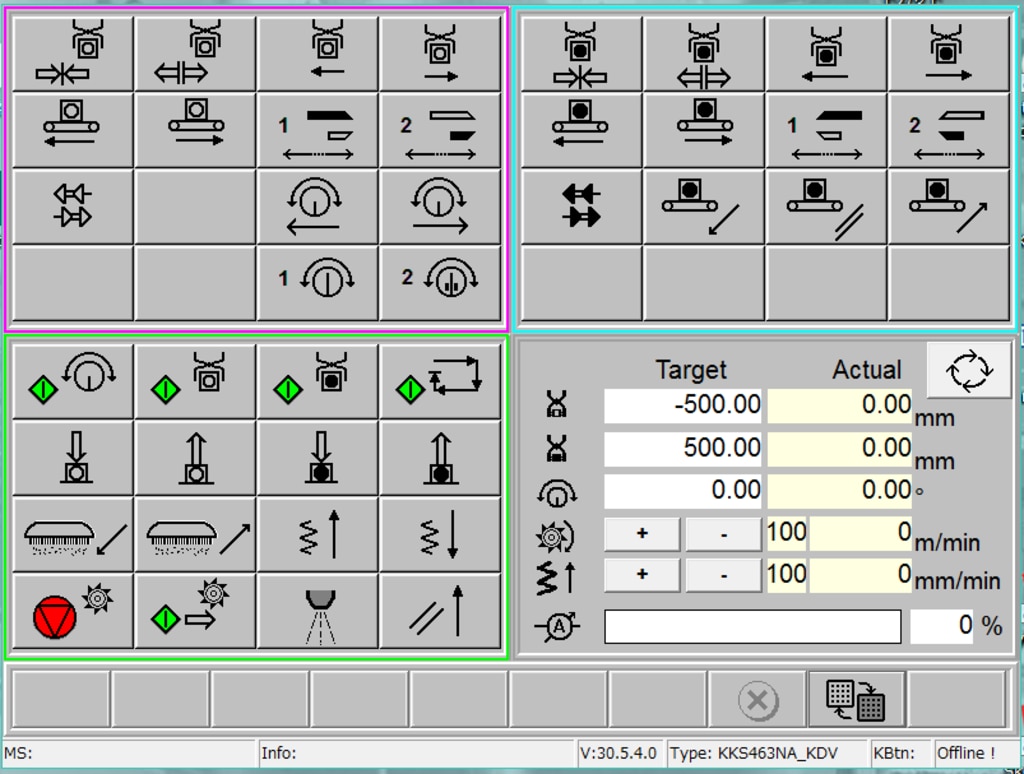

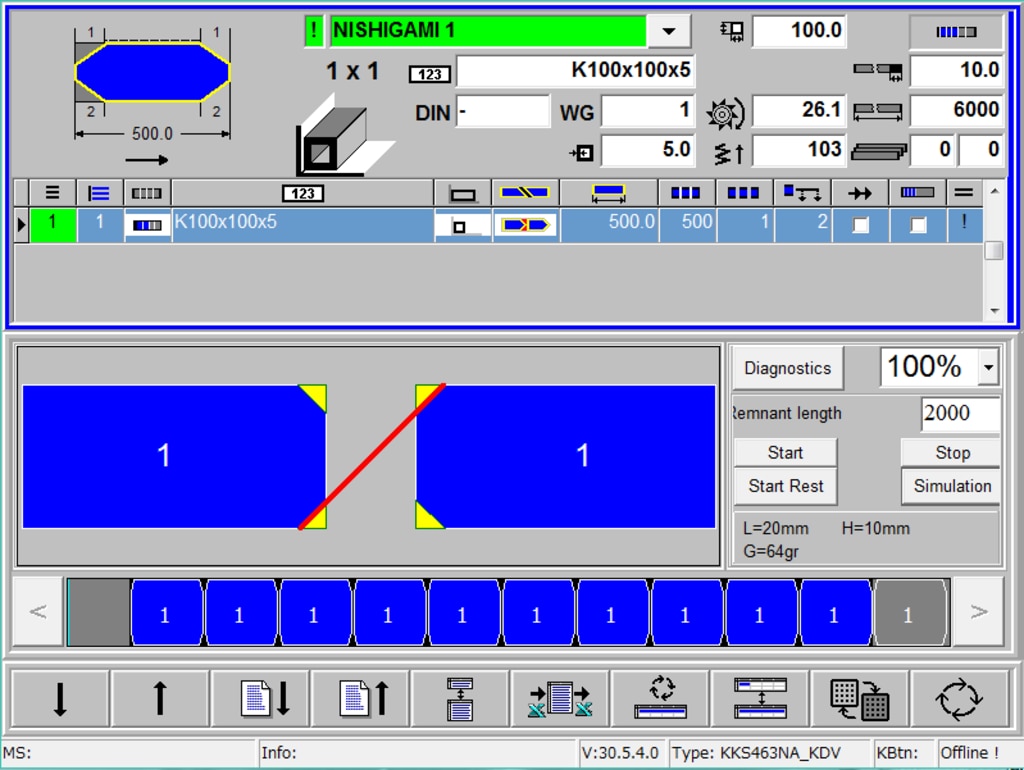

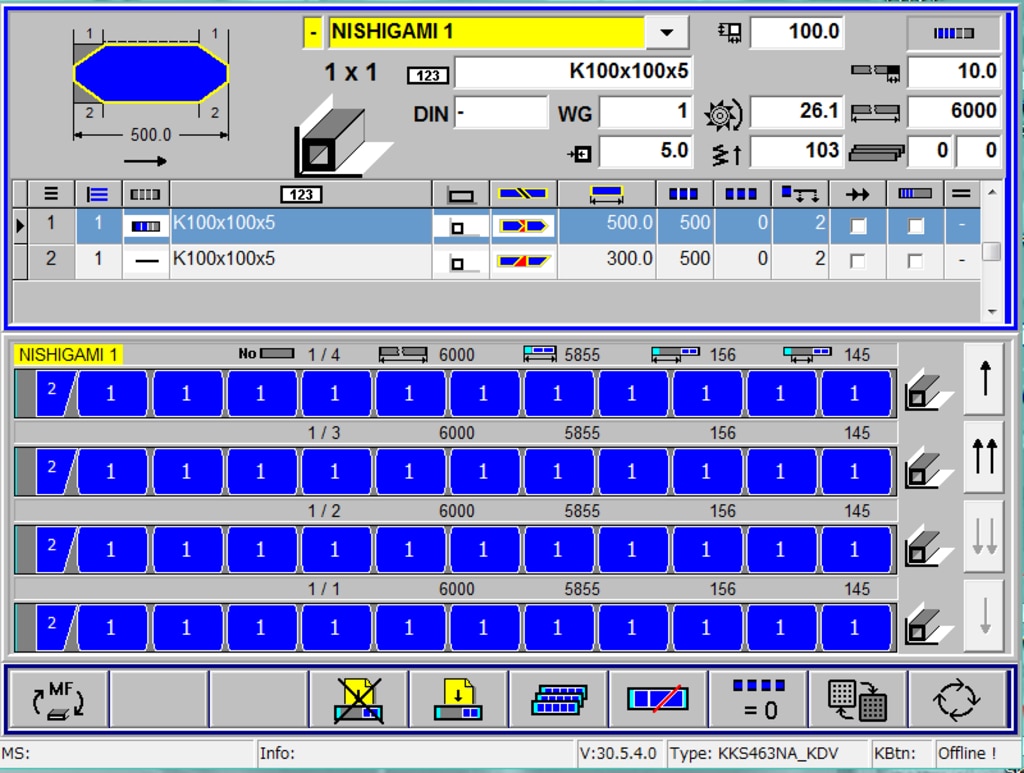

Fully automatic metal saw blade cutting machine KKS463NA installation example