A major change in connecting work

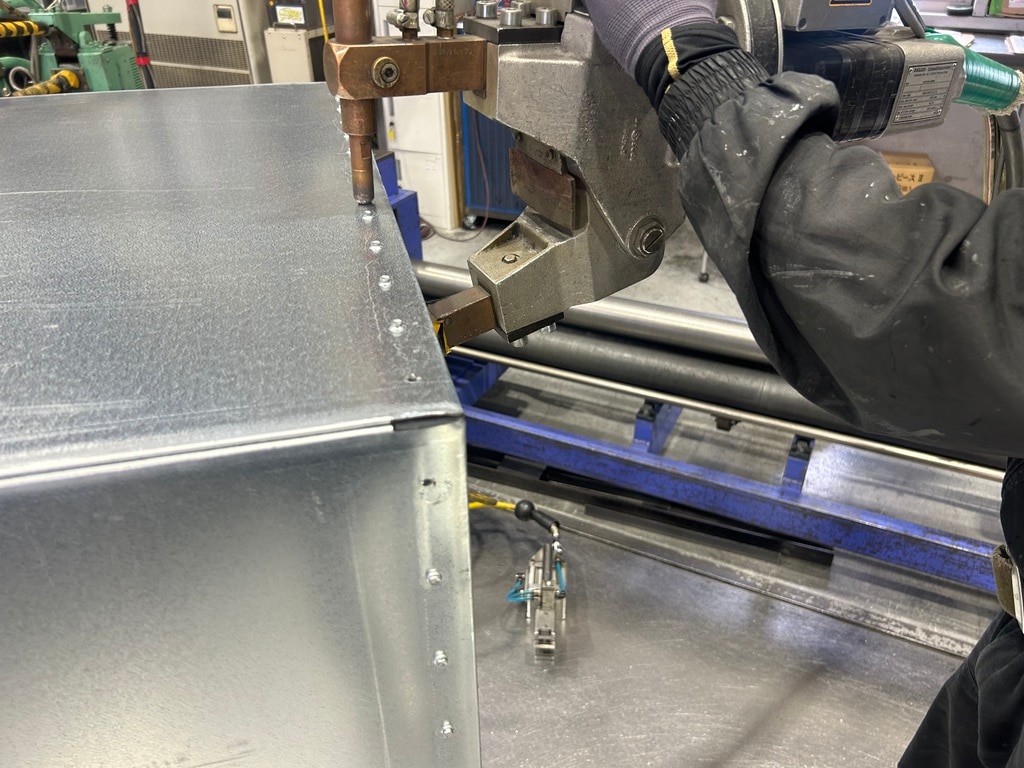

With spot welding

Reduced man-hours by one-third

Koushin Equipment Co., Ltd.

Representative Director Yukinobu Doguchi

Spot welding machineintroduction example

Koushin Equipment Co., Ltd.

Representative Director Yukinobu Doguchi

Spot welding machineintroduction example

Company name

Koushin Equipment Co., Ltd.

location

〒596-0817

2-1-25 Kishinookacho, Kishiwada City, Osaka Prefecture

Number of Employees

26 people

Business details

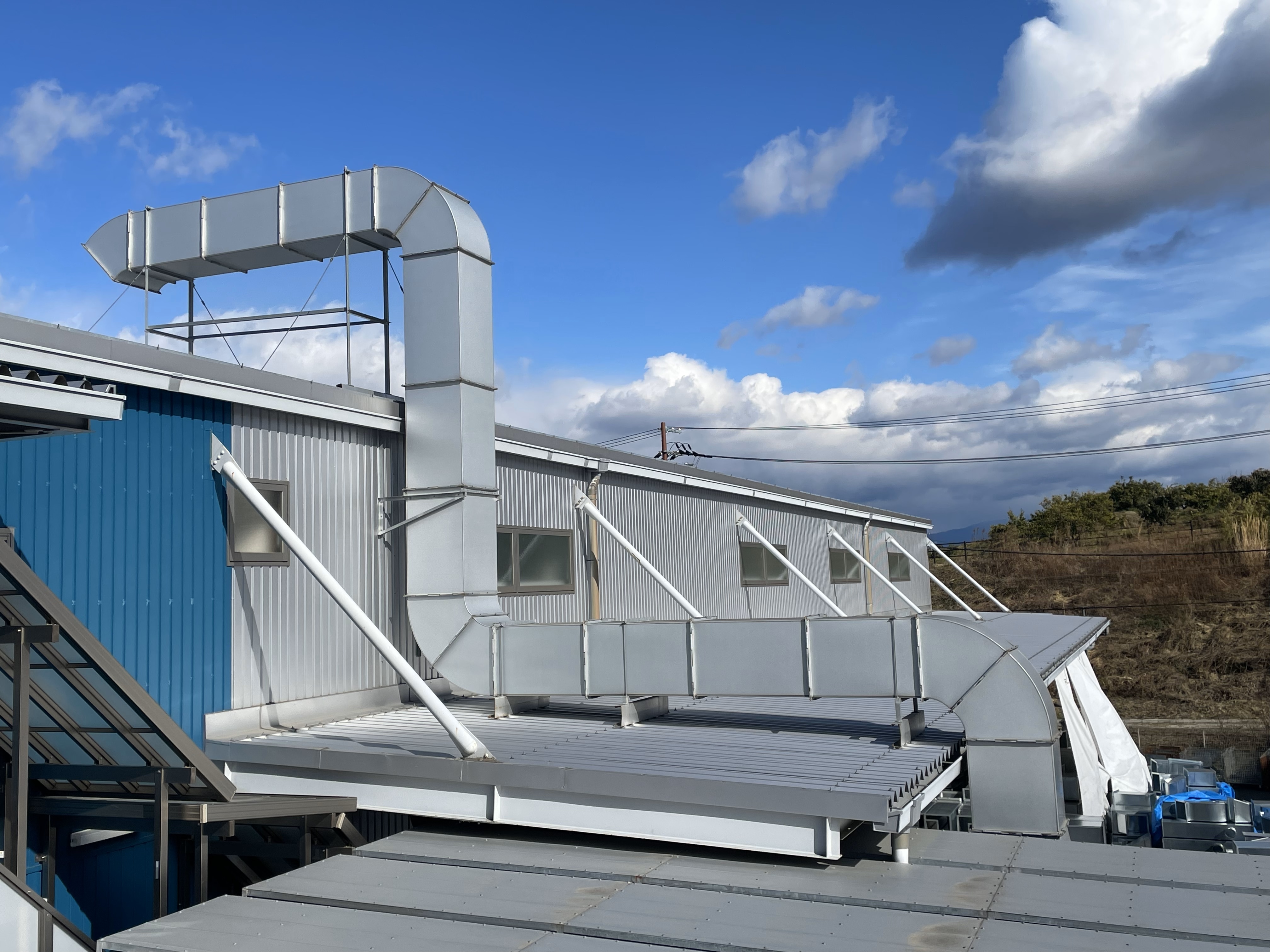

Air conditioning and smoke exhaust duct manufacturing and installation

Introduction products

Spot welding machine DALEX3328

URL

https://kaburaku-koushin.com

the purpose

- Reduced man-hours required for duct joining work, improved work efficiency

- Welding of dissimilar metals

assignment

- Riveting requires many steps

- Large ducts have more than 60 joints

effect

- Work processes are consolidated into one, significantly reducing man-hours and work time

- Increased production capacity has led to an increase in orders for large projects exceeding 5m

For detailed specifications of the spot welding machine, click here

Koushin Equipment Co., Ltd.

Address: 2-1-25 Kishi-no-oka-cho, Kishiwada City, Osaka Prefecture, 596-0817

TEL 072-489-2121

URL https://kaburaku-koushin.com