Repeatability, Efficiency, Quality

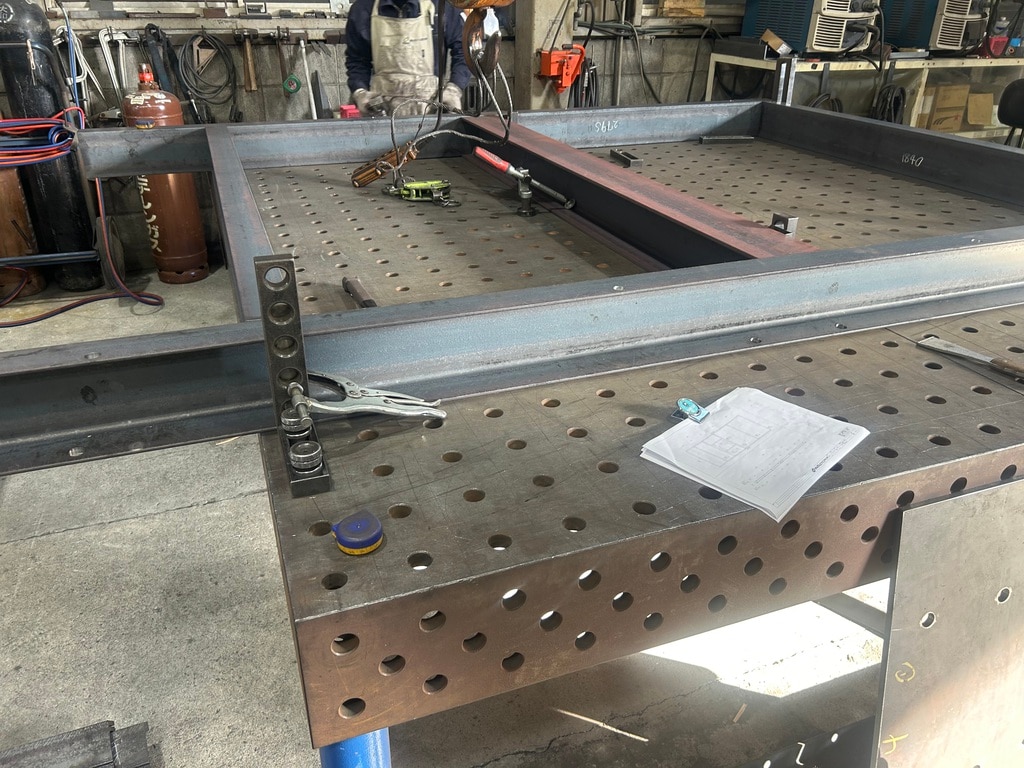

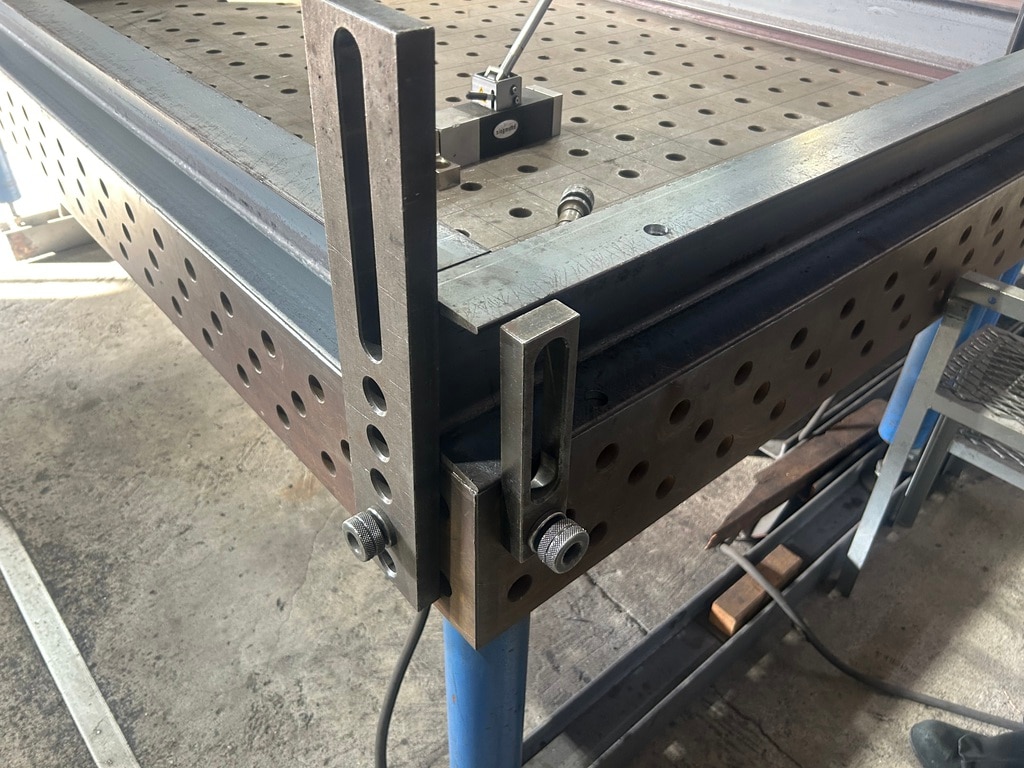

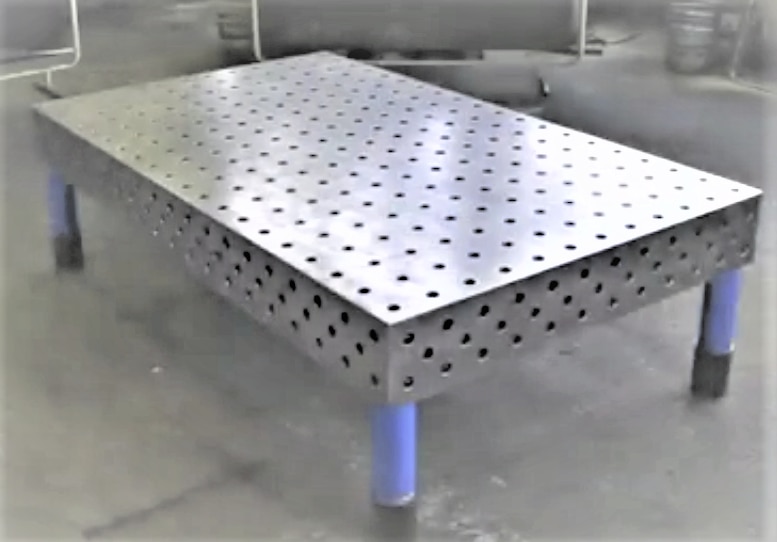

3D welding table

It will answer all your questions

Okazoe Manufacturing Co., Ltd.

Representative Director, Mr. Kei Okazoe

Hidenobu Shuto, Executive Officer, Manufacturing Department Manager and Factory Manager

3D welding tableintroduction example