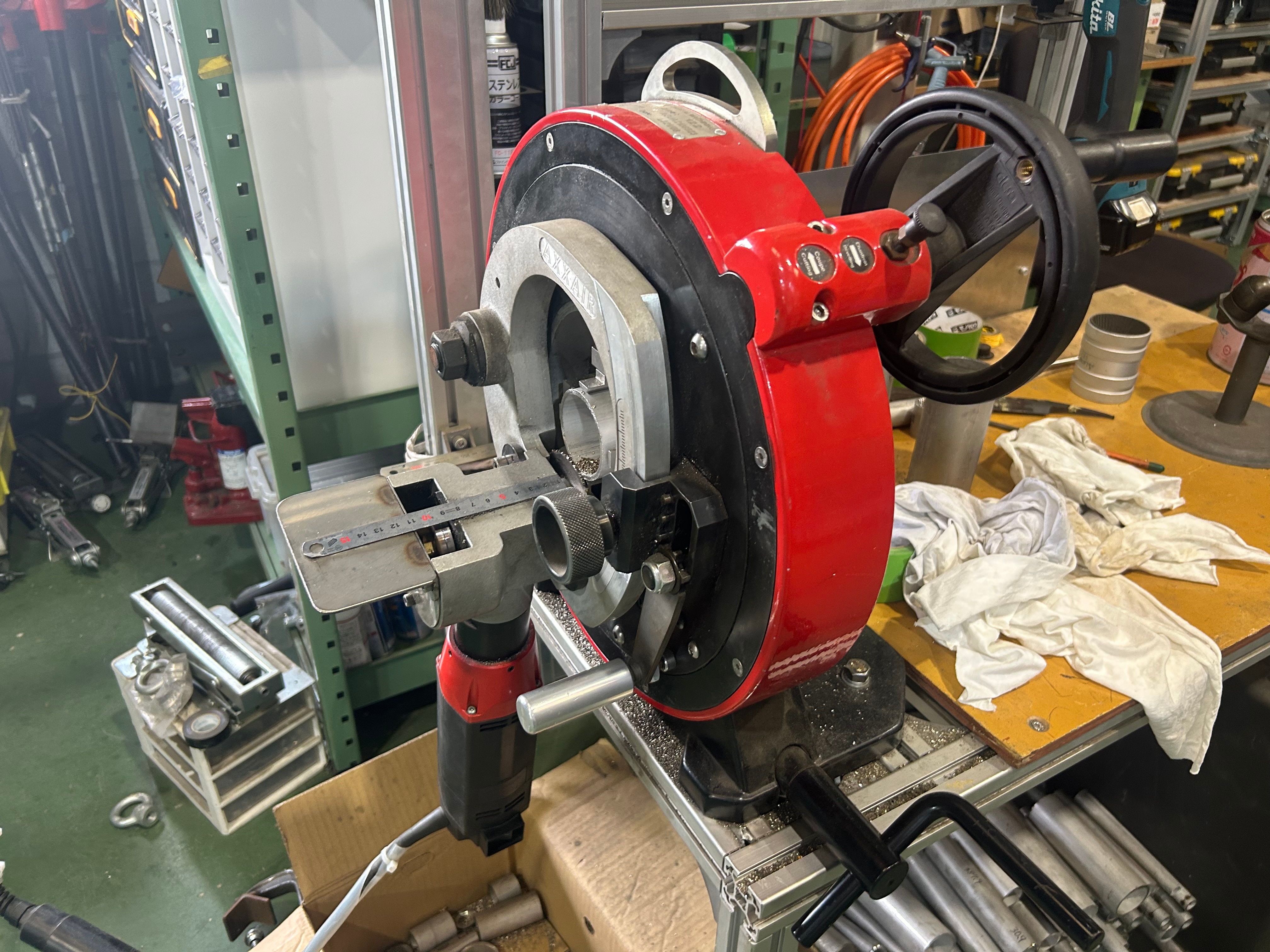

When he went to help out at a construction site, he saw a rotary cutting machine being used by another company, became interested in its performance, and began considering purchasing one.

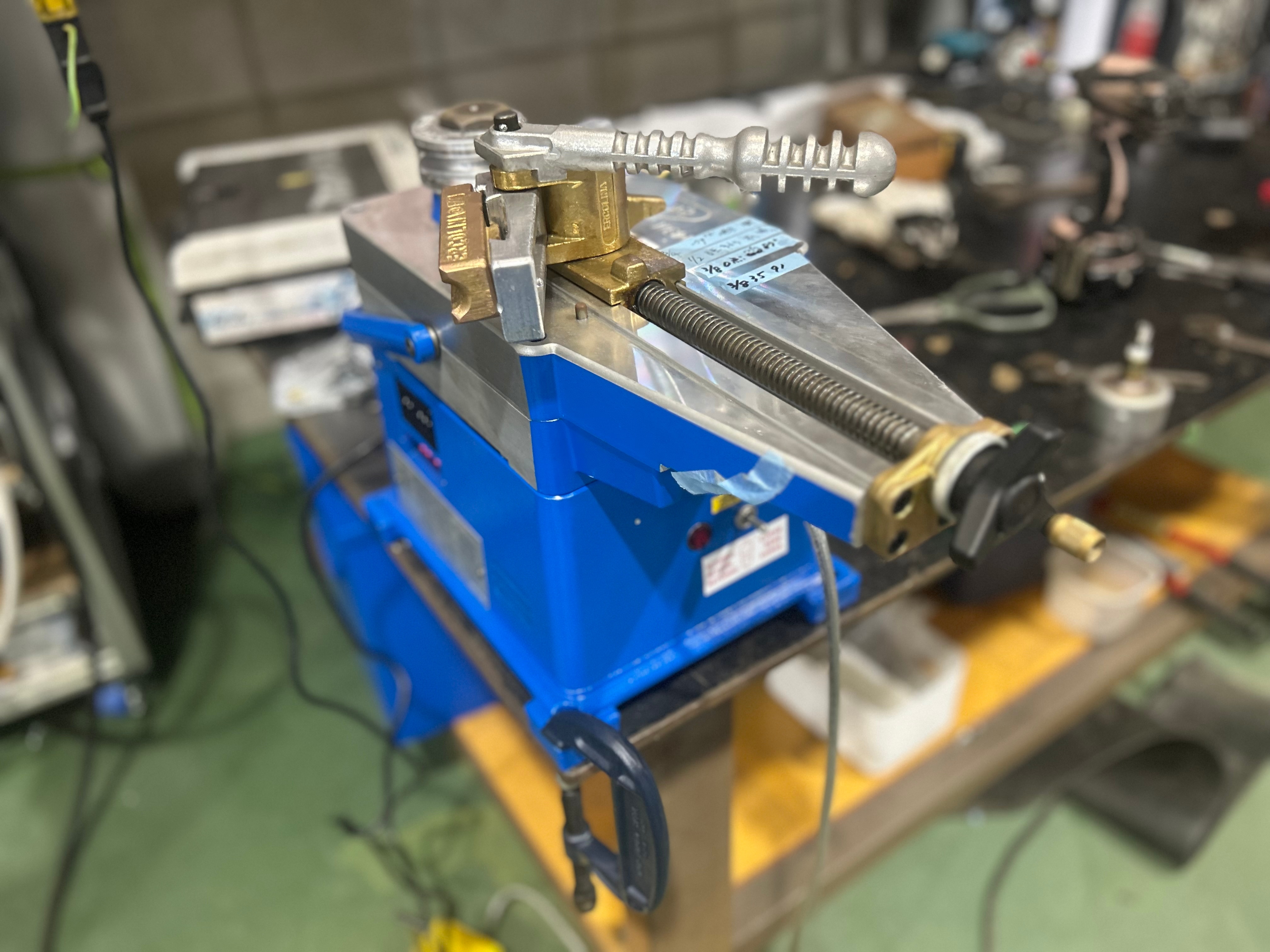

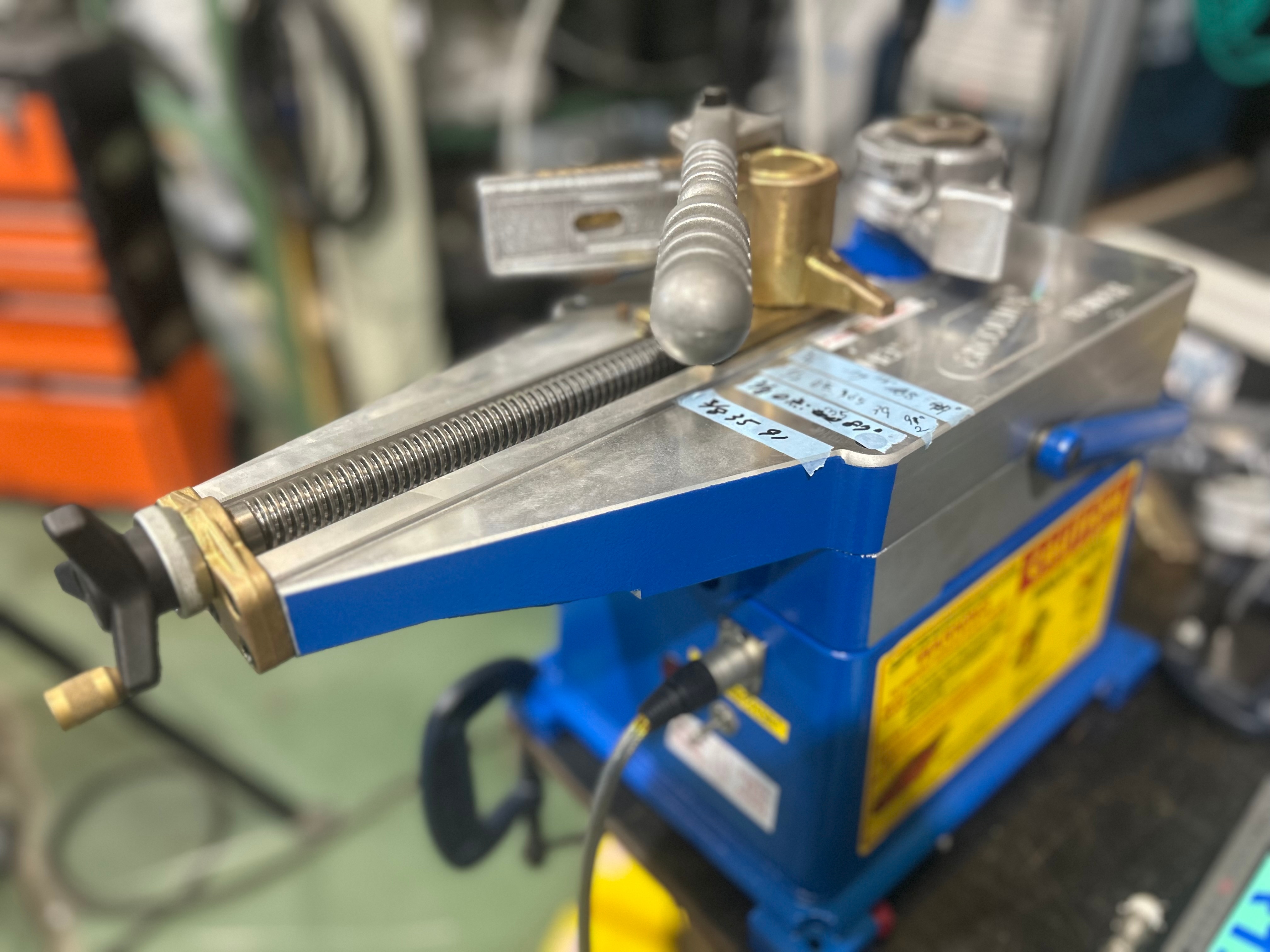

Previously, pipes were cutting using a band saw, but it was very difficult to cutting at right angles. After cutting, the pipes were connected together, a ruler was placed on the pipes to check that they were parallel, and they were spot welded while hitting them with a hammer to adjust them. In particular, if the right angle was not achieved, it took a lot of man-hours and effort to correct it.

For outdoor pipes of about 4m in length, some degree of adjustment is possible, but for short pipes that fit inside equipment, even the slightest misalignment makes it impossible to connect, and precise right angles are required. As the number of equipment manufacturing contracts increases, the company realized that the accuracy of pipe cutting is directly linked to the quality of work, and decided to introduce the machine.

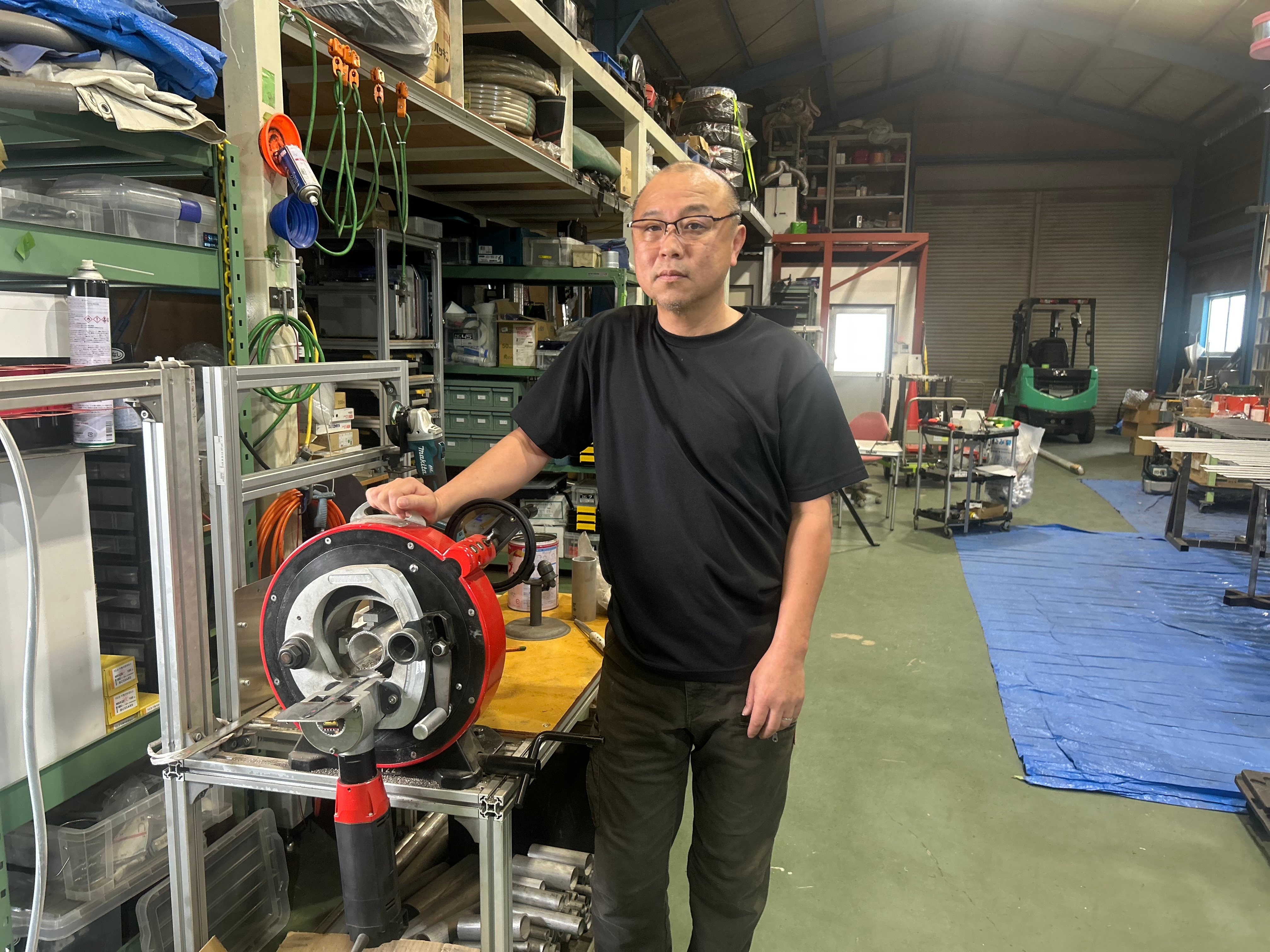

After comparing several rotary cutting machines, they decided to install this machine because of its excellent balance of cost and performance.