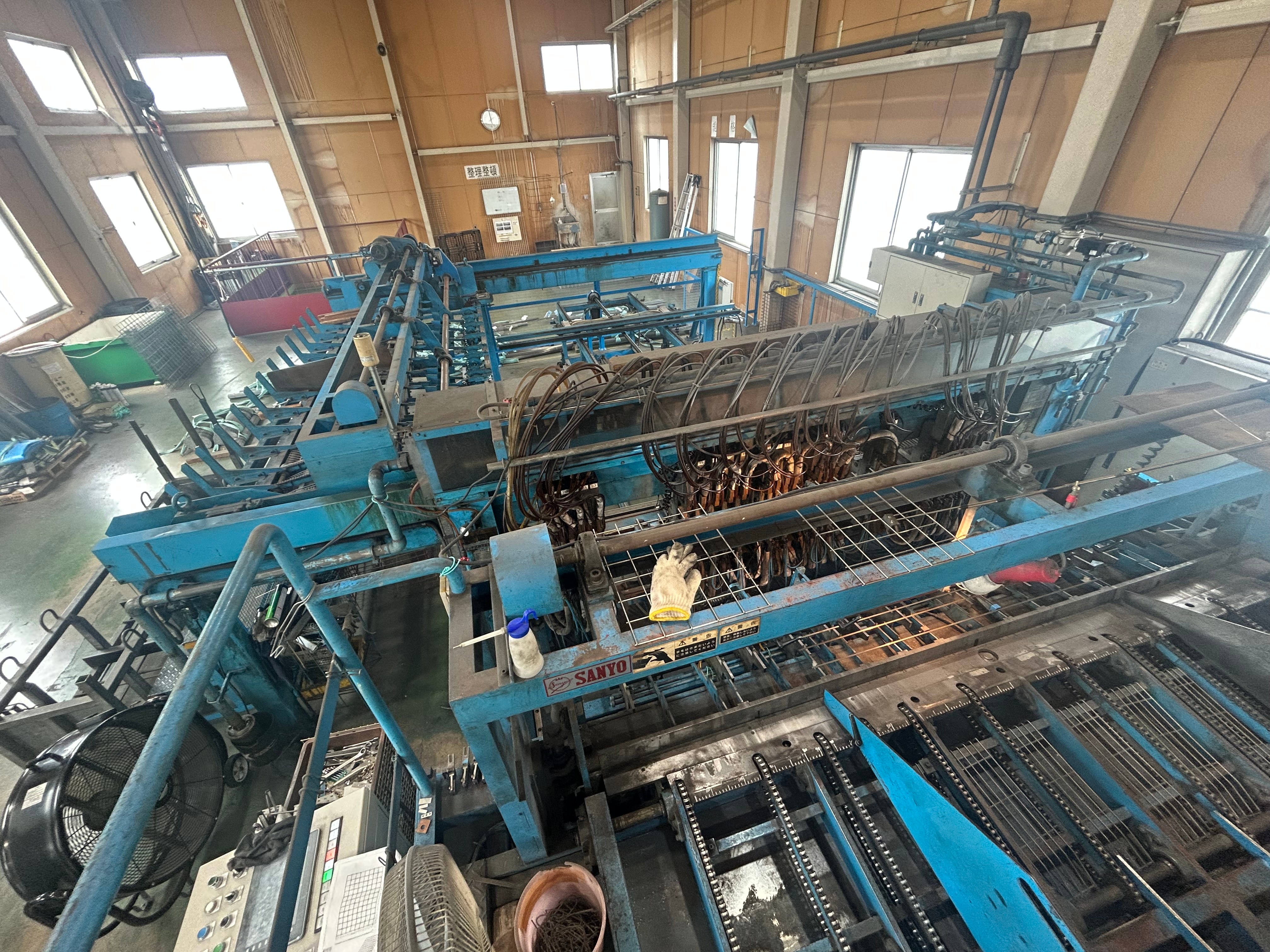

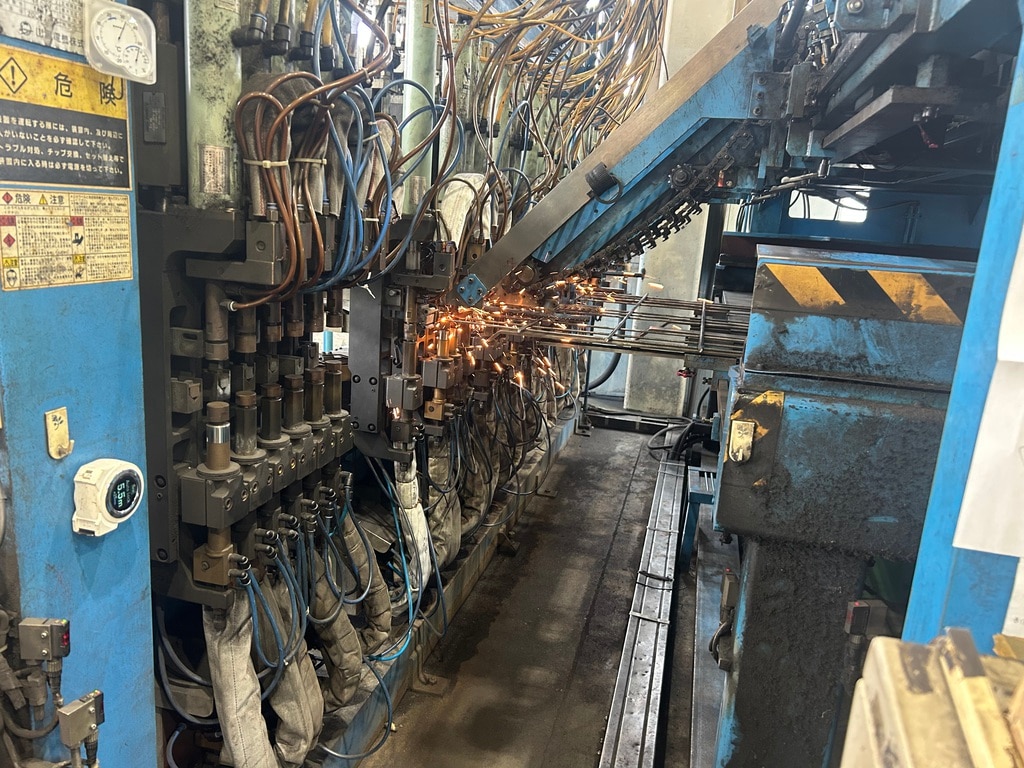

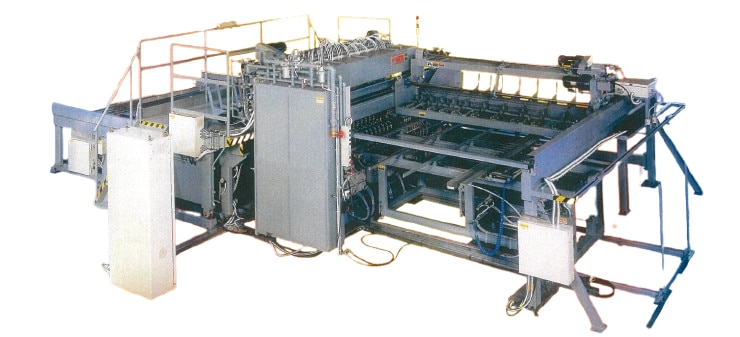

By introducing a wire mesh multi-spot welding device manufactured by Sanyo Electric Co., Ltd., Hikari Kogyo Co., Ltd. has seen a significant improvement in production efficiency. Previously, two workers had to manually weld approximately 50 pieces of wire mesh per day, but after the introduction, one worker was able to weld 150 pieces. By automating the process, production capacity increased by approximately six times, enabling the company to build a stable manufacturing system that does not rely on human labor. This has resulted in direct cost reductions, and significant results have been achieved in terms of both efficiency and profits.

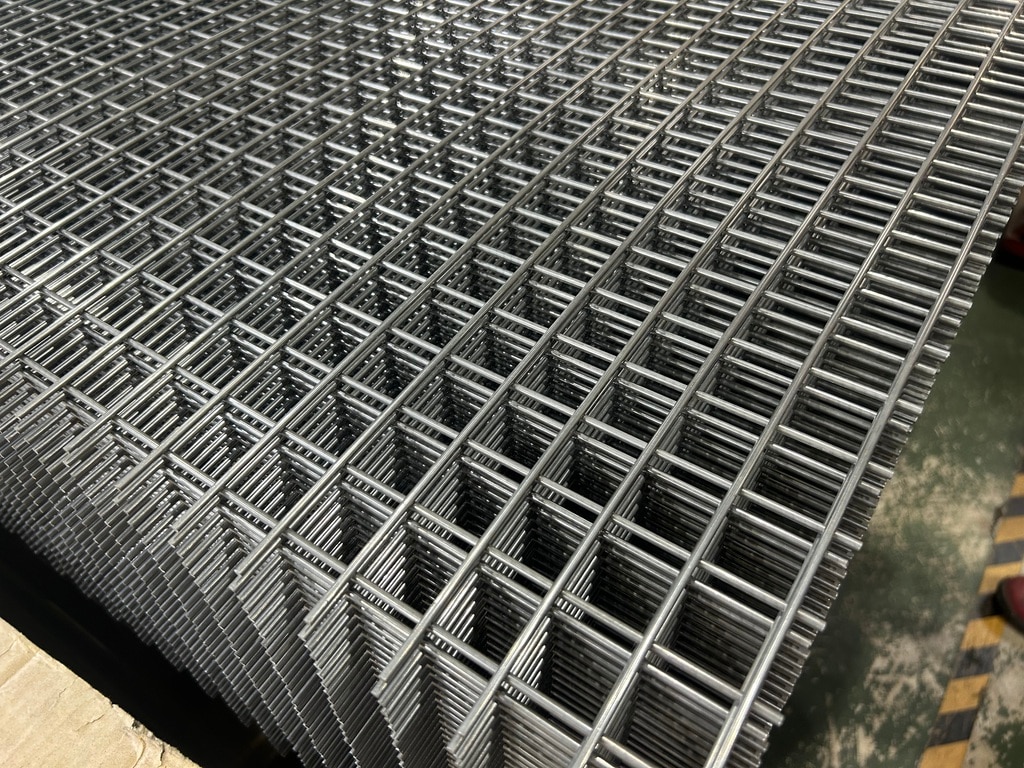

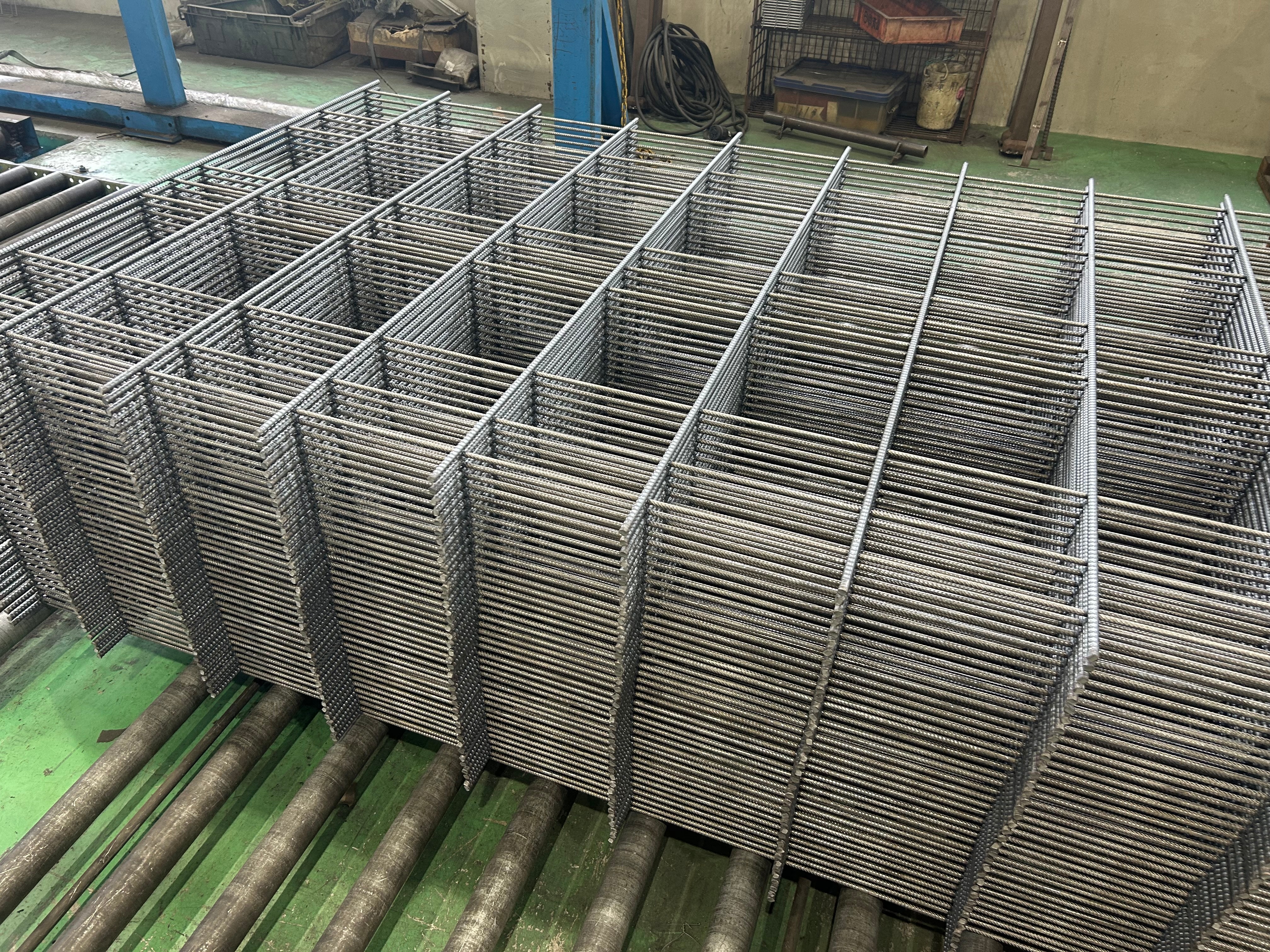

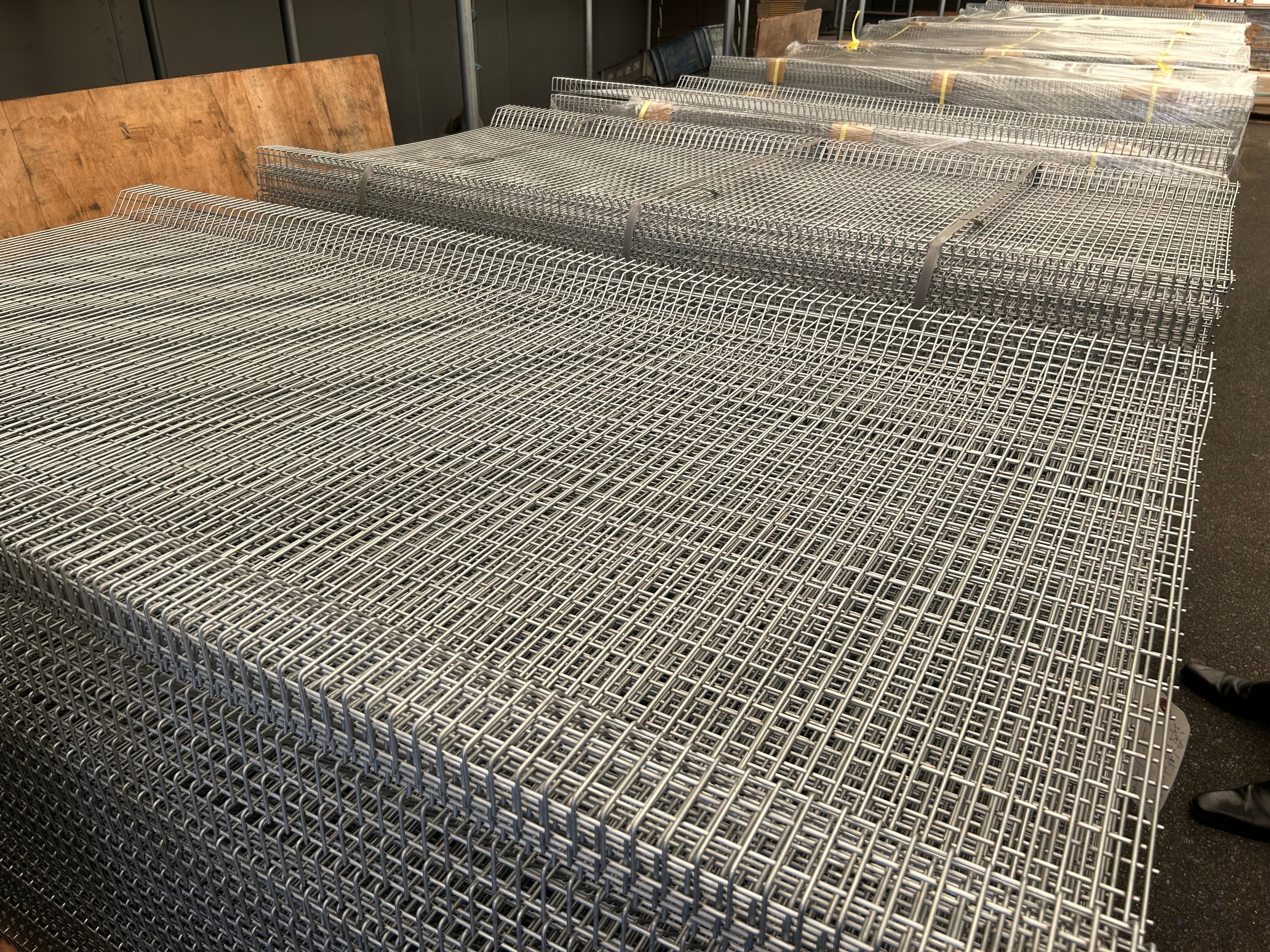

Another major benefit was that the specifications of the wire mesh multi-spot welding equipment we introduced matched the technical needs of Hikari Kogyo to a high degree. We were able to handle fine-pitch wire mesh that other companies found difficult to handle, and this has been well-received, leading to an increase in new orders.

In fact, they are increasingly receiving requests from other companies in the same industry that mainly manufacture standardized products to manufacture custom-made fences and safety barriers. Their technical capabilities that allow them to do things that "no one else can do" have led to trust and differentiation from customers, and they see great potential for future development.