What is metal saw blade? Explanation of materials and blade types!

"What is metal saw blade?" "Which material should I choose?" "What is the best blade shape?" These are questions that anyone involved in cutting metals may have had at least once.

This article provides a comprehensive explanation of everything from the material characteristics of cutting blades to the differences between the main blade types, as well as tips for selecting the pitch that determines the performance of metal saw blade cutting machine.

Table of contents [hidden]

- 1.Whatis metal saw blade?

- 2.About the material of metal saw blade

- 3.cutting with metal saw blade

- 4.Aboutthe blade type of metal saw blade

- 4.1.高低刃(HZ・C)

- 4.2.交互刃(チドリ・BW・面取り)

- 4.3.溝刃(ノッチ・CB・BN)

- 5.Regarding pitch selection

- 6.About SZ (depth of cut per tooth)

- 7.metal saw blade angle

- 8.Aboutcoating

- 8.1.鋸刃の耐摩耗性の向上

- 8.2.生産性の向上

- 8.3.費用と作業性の改善

What is metal saw blade?

metal saw blade is a circular saw made of metal for cutting.

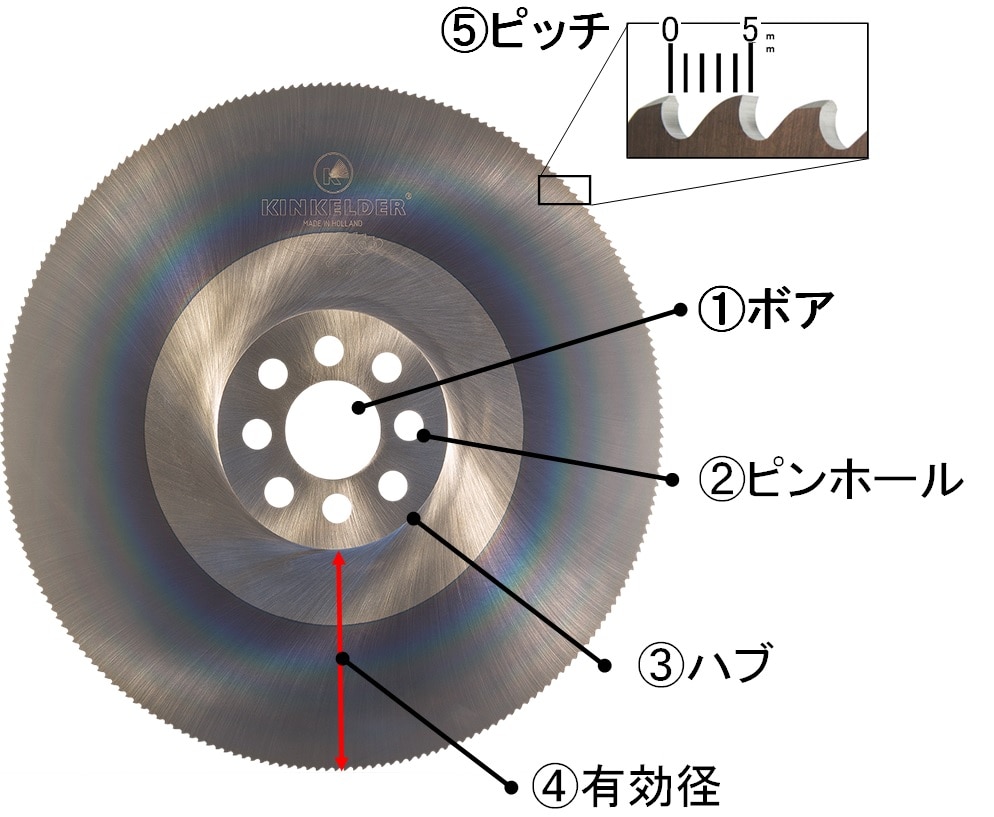

There are names for each part as follows:

①ボア

切断機械と接続する穴部。径(大きさ)は機械メーカー、機種により異なります。

ボア径は、32h(ボア径32mm)、50 h(ボア径50mm)と表されます。

②ピンホール

切断機械と接続する際の補助となる穴部。

ピンホールの数、径(大きさ)は機械メーカー、機種により異なります。

③ハブ

切断機械と接続する際の、機械と接触する中心端面。

④有効径

切断できる範囲です。研磨するたびに、減少します。

⑤ピッチ

鋸刃の山と山の間の長さを表します。上記図の場合、ピッチ5mm P5と表します。

When expressing the model of metal saw blade,

315Φ (outer diameter) x 2.5t (thickness) x 32h (bore diameter) x P5 (or number of teeth) + tooth type

and each has its own meaning.

About the material of metal saw blade

High-speed steel, also known as metal saw blade, was developed to make up for the low softening resistance of tool steel at high temperatures and to be used as a tool material that enables cutting of metal materials at higher speeds. It is also called high-speed tool steel.

The name "HSS" is an abbreviation of "high speed steel," and high speed steel, abbreviated as HSS, is made by adding large amounts of metal components such as chromium, tungsten, molybdenum, and vanadium to steel in order to increase its hardness and resistance to softening at high temperatures. After undergoing heat treatment such as quenching, the steel is polished to shape it for use.

Compared to cemented carbide, it has inferior wear resistance but is superior in toughness and can be cut at higher speeds.Today, powder metallurgy is used to refine the structure and create even higher alloys.

"Sintered high-speed (tool) steel" (powdered high-speed steel) and highly wear-resistant coatings such as titanium nitride (TiN) on the surface by physical vapor deposition (PVD) are widely used, and these and other hard alloys are used as materials for tools used in metal processing in areas where the toughness is insufficient, mainly drills, end mills, and metal saw blades.

In addition, high-speed steel with cobalt added is specifically called "cobalt high-speed steel" and has better resistance to tempering and high-temperature hardness, and is used for drilling stainless steel, which is exposed to higher temperatures during processing.

The Japanese Industrial Standards (JIS) specifies 13 types of high-speed steel as "JIS G4403." Among these, high-speed steel is identified by the symbol ``SKH'' preceding the number, which stands for Steel, Kougu (tool), and High-speed.

Excerpt from Wikipedia

Remember that metal saw blade are made of HSS (high speed steel) and cobalt high speed steel. In other countries, they are called M2 and M35.

About cutting with metal saw blade

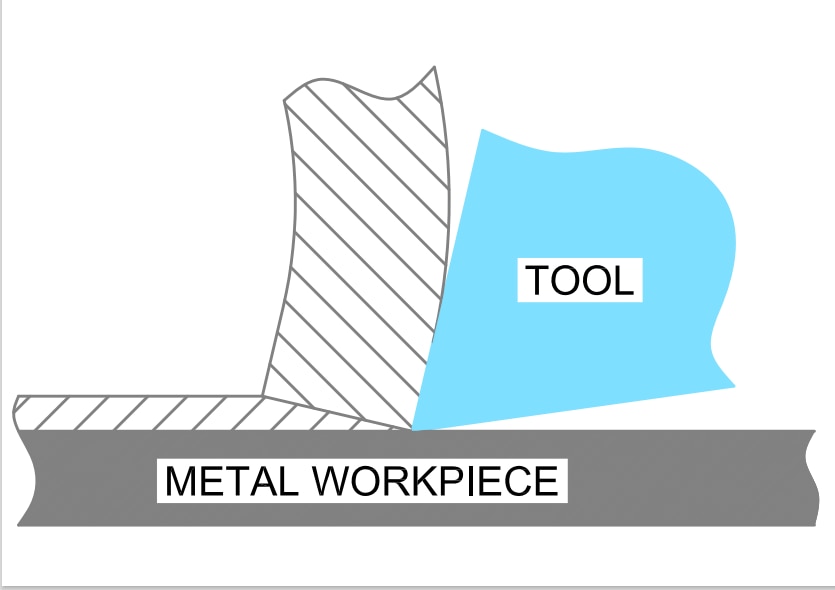

The diagram below shows how the cutting edge of metal saw blade penetrates the material.

*Excerpt from Kinkelder materials

As you can see from this diagram, the cutting edge of metal saw blade digs into the material(cutting)、

It is metal saw blade cutting to make chips and generate heat due to friction.

*The above process makes metal saw blade saw bladewearoccurs.

About the blade type of metal saw blade

We will introduce three typical blade types of metal saw blade.

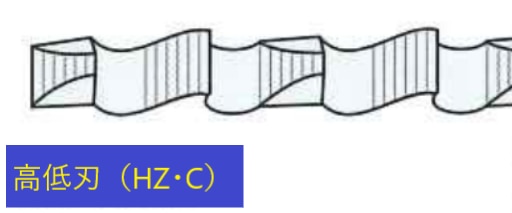

High and low blade (HZ・C)

It has been consideredthe basic blade shapefor metal saw blade.

被切断材:ムク材や厚肉材向け

切削抵抗:小(2刃で切粉3分割)

面粗度:粗い ピッチ:4以上

備考:難削材に対応

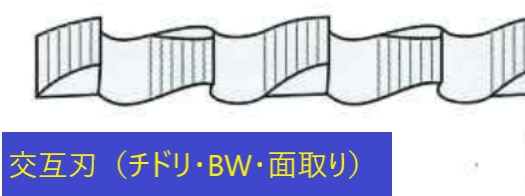

Alternating blades (Chidori, BW, chamfered)

This is the basis for thin-walled pipes, etc.

Material to be cutting: For thin-walled pipes

Cutting resistance: Medium (2/3 of saw blade)

Surface roughness: Fine Pitch: 3-4

Note: For low speed/manual machines

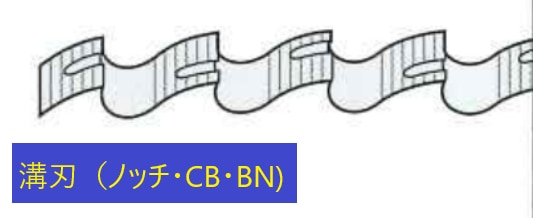

Groove blade (notch, CB, BN)

The latest technologyis here.

Materials to be cutting: thin-walled pipes, etc.

Cutting resistance: Large (one blade splits chips into two)

Surface roughness: Fine Pitch: 4-9

Remarks: For automatic machines. High speed rotation produces beautiful cutting surfaces.

*Requires mechanical rigidity and coating. Not suitable for angle cutting (can be used if angle cutting is not an issue)

These three blade shapes are the basics, but there is also a track record of using grooved blades on solid wood with an emphasis on surface roughness, andthere is activeresearch into the technology of blade shapes other than those mentioned above (for example, uneven pitch, etc.).

*The usage limits of metal saw blade and the criteria for determining whether something can be cut or not vary from user to user, so the basic principle is to ultimately determine the blade type specifically for the user after conducting actual cutting tests.

We will support you in establishing such judgment criteria.

About pitch selection

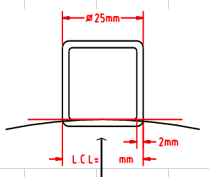

※Important thingscutting lengthTo check ※

cutting length is the longest distance that saw blade cuts into the material.

*From Kinkelder materials

The above diagram shows how our Kaltenbach cutting machinecuts a square pipe from bottom to top, and shows the part of the square pipe where cutting length (the longest distance that saw blade cuts into the material) is longest.

The pitch (number of teeth) of saw blade must be determined based on cutting length that places a load on this first blade.

Why is it necessary to select the pitch (number of teeth) according to cutting length?

If one blade cutting in from below and is pushed up to cut the material, Material chips and heat occurs.

The chips from this material become a load, causing wear on the blade and affecting the wear of the saw blade.

In addition, since saw blade cuts along the entire cutting length, chips are also generated along the entire cutting length.

The chips are wound up like a spring and collected in a part called the base of the blade.

As you may have guessed, a pitch that is small for a long cutting length will clog (chips will accumulate at the bottom of the blade), and conversely, a large pitch for a short cutting length will not improve cutting efficiency.

In addition, the amount of cutting chips also changes depending on the SZ value, so this must also be taken into consideration. Therefore, it is necessary to select the appropriate pitch depending on the item being cut, the machine and saw blade.

For example, in our company based on the above Pitch Selection Process As an example, the load on the blade (denoted as SZ = depth of cut per blade) depends on the material to be cutting cut and the machine to be cutting cut, but if we assume a Kinkelder high technology saw blade with high rigidity Fully automatic cutting machine machine (cutting speed 150m/min), we calculate a load of SZ = 0.08mm depth of cut per blade, In a 50 square 2.3t pipe, the pitch is 10 can be calculated as follows.

*Details of the calculation are omitted due to space restrictions. The pitch will vary depending on cutting speed of the cutting machine, so we will support you.

About SZ (depth of cut per tooth)

*It depends on the machine you are using.

What is the amount of cut? It is about how much cutting is done per blade, and this can be said to be correlated with the blade pocket (blade bottom) and cutting length (commonly known as clogging).

It is also affected by the rigidity of the cutting machine, and manual machines are set to small values, while high rigidity machines are set to high values. In addition, the thickness of saw blade and the side shape of saw blade (POWER shape) may also affect the setting.

Basically, from the perspective of wear, the minimum rounding up at cutting time for manual machines is 0.03 mm for human power, etc., and to about 0.13 mm for heavy cutting with hydraulic feed at relatively low speeds on Kultenbach cutting machines.

Also, the SZ approach needs to be changed depending on the material being cutting.

(Non-ferrous = high, spring steel = low).

About the angle of metal saw blade

*Changing this might change your cutting results.

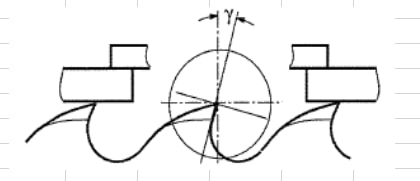

γ: Rake angle Varies depending on shape and material

Iron: Basic: 18 degrees (Kinkelder recommended) Aluminum etc: 25 degrees

*Reference: 400-500N/mm² pipe

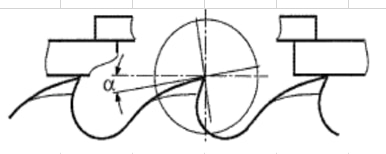

It is advisable to consider where the blade enters the material on your machine. Each company has its own differences (approach angle, swing, straight ahead).

In general, the harder the cutting material, the smaller the angle (shear rather than cutting)* approaching tipped saw blade cutting (rigidity and torque are required).

Iron: Basic: 8 degrees (Kinkelder recommended) Aluminum: 12 degrees

*Reference: 400-500N/mm² pipe

It is advisable to consider the position where the blade enters the material on your machine. Each manufacturer has their own differences (entrance angle, swing, straight movement).

Generally, the harder the material being cutting, the smaller the angle should be.

From the above, it can be said that the sharper the blade is, the easier it will dig into it and the more likely it will chip, and the thicker it will be, the stronger it will be, but the harder it will be to cut.

About coating

These days, there are black cutters and gold cutters, right?

There are three purposes for why coating is applied.

Improved wear resistance of saw blades

① Improved surface hardness by coating (1,500 to 3,500 HV)

As a reference hardness

HSS: 760-840HV TCT (tungsten carbide): about 1400HV

② Smooth the surface and reduce frictional resistance on the cutting edge and overall surface

3) Reduction of heat damage to the saw board during cutting

④Prevention of oxidation on the saw blade surface

Increased Productivity

(1) Can do cutting quickly → Can do cutting speed quickly. Can increase the amount of infeed.

2. Longer cutting edge life due to reduced wear on the cutting edge

3) Reduction of burrs

④ Cutting oil, etc. can be reduced

Cost and workability improvements

① Increased production volume per hour

②Reducing the burden on machines

③Reduction of consumable costs due to longer life (especially reduction in number of polishing times)

④Improvement of deburring work by reducing burrs

⑤Reduction of saw blade replacement time, etc.

6. Reduced consumption of cutting oil reduces consumable costs and improves the working environment

Coated saw blades are expensive, but if their lifespan is extended, the cost can be reduced by the number of times they are sharpened x the number of times they are stretched, especially for metal saw blade that require resharpening.

In the end, there are stories of cutting costs being cut in half simply by switching to a high-tech saw.

We will give you a trial calculation, so please give us a call.

Thank you for reading to the end.

You can download metal saw blade catalog for free from the button below.