Why are UNIDACK filling machines so accurate and safe? The secret lies in "high-precision load cell technology"

When filling LPG,even the slightest weight error can lead to concerns about safety and transaction reliability. Therefore, selecting a filling machine that can accurately measure is extremely important. In this article, we will explain Kubota's cutting-edge technology and explain why the UNIDACK filling machine is so accurate.

Table of contents [hidden]

- 1.Why the UNIDACK filling machine can "fill accurately"

- 1.1.Thekey is "Kubota high-precision load cells"

- 1.2.Typesof Load Cells

- 1.3.Kubotaproduces load cells in its own factory

- 1.4.100% inspection is carried out based on JIS standards

- 1.5.Inspection by a service technician at the delivery site

- 2.What are the guidelines and timing for considering updating your LPG filling machine?

- 3.Introducing the new, more advanced "Resin-filled Explosion-proof Digital Load Cell"

- 4.Introducing the latest LPG filling machine "S-EA-IV" | A next-generation filling machine that combines safety and precision

- 5.Summary_

Why the UNIDACK filling machine can "fill accurately"

The key is "Kubota high-precision load cells"

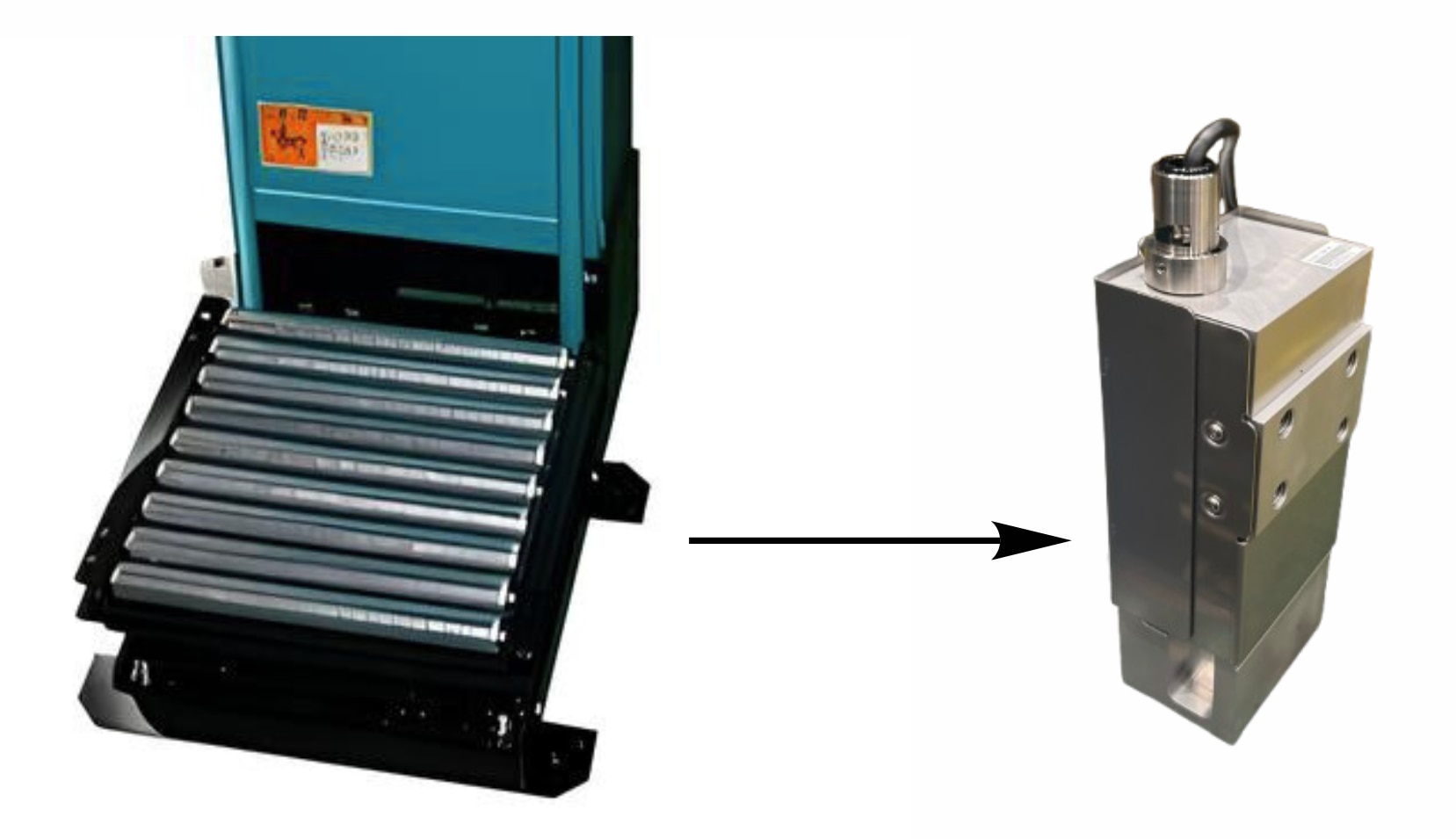

The weighing section of the filling machine is equipped with a load cell, which detects the mass by converting the "strain" caused by the weight of the cylinder or LPG into a voltage change (strain load cell).

The UNIDACK filling machine uses a one-point load cell mechanism, which has no parts that wear out, so it can maintain high filling accuracy for a long time without requiring maintenance.

The load cell is mounted under the free roller of the filling machine.

Load Cell Types

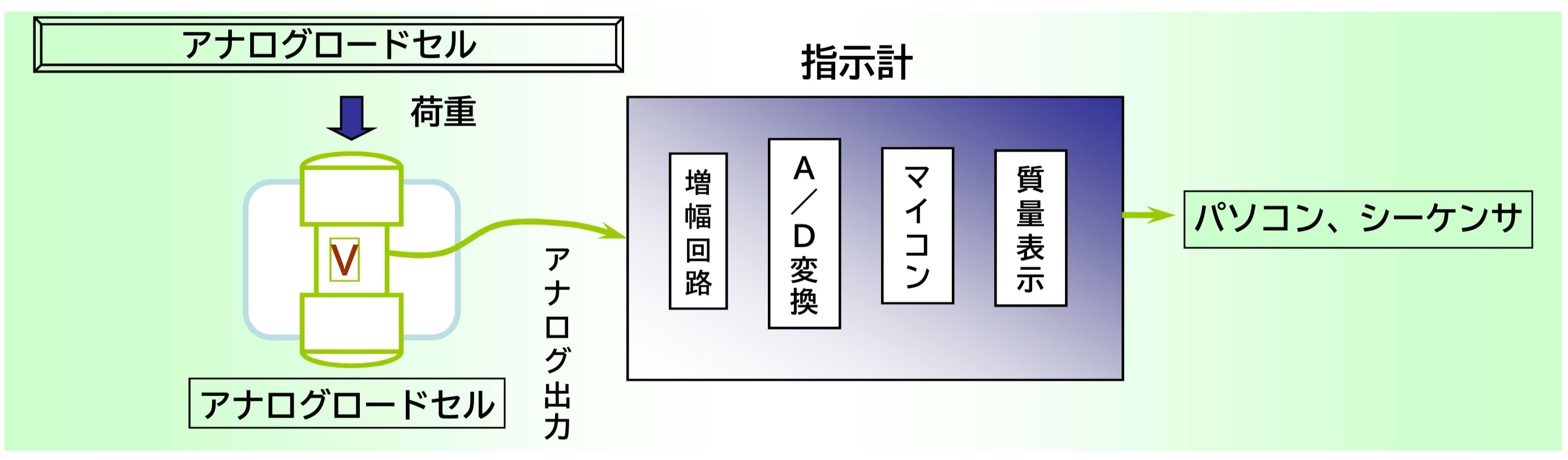

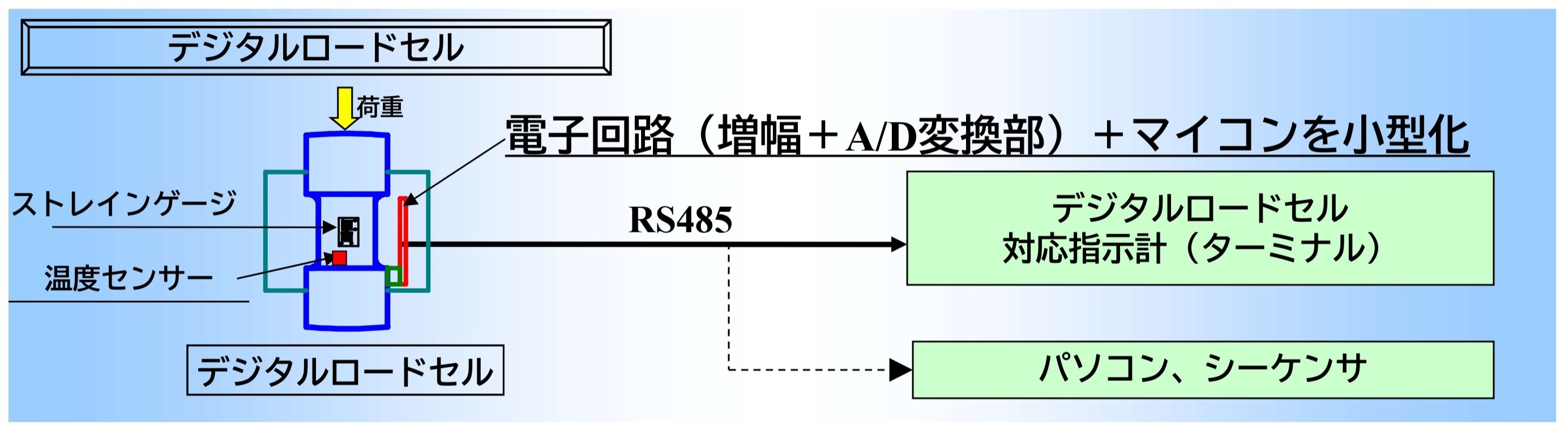

There are two types of strain load cells: analog and digital. Kubota uses digital load cells.

Analog Load Cell

The analog signal is output from the load cell via a cable and converted to a digital signal by the indicator.

Digital Load Cell

The load cell itself incorporates an electronic circuit (amplification + A/D conversion section) and a microcomputer, which converts the signal into a digital signal before outputting it.It also has a built-in temperature sensor, which automatically corrects errors caused by changes in the ambient temperature.

Kubota produces load cells in its own factory

Kubota, the manufacturer of the filling machine, produces load cells in its own factory, and there are only a handful of scale manufacturers that produce load cells.

This allows us to strictly control all processes, from design to manufacturing and inspection, and ensures a stable supply of high-quality load cells.

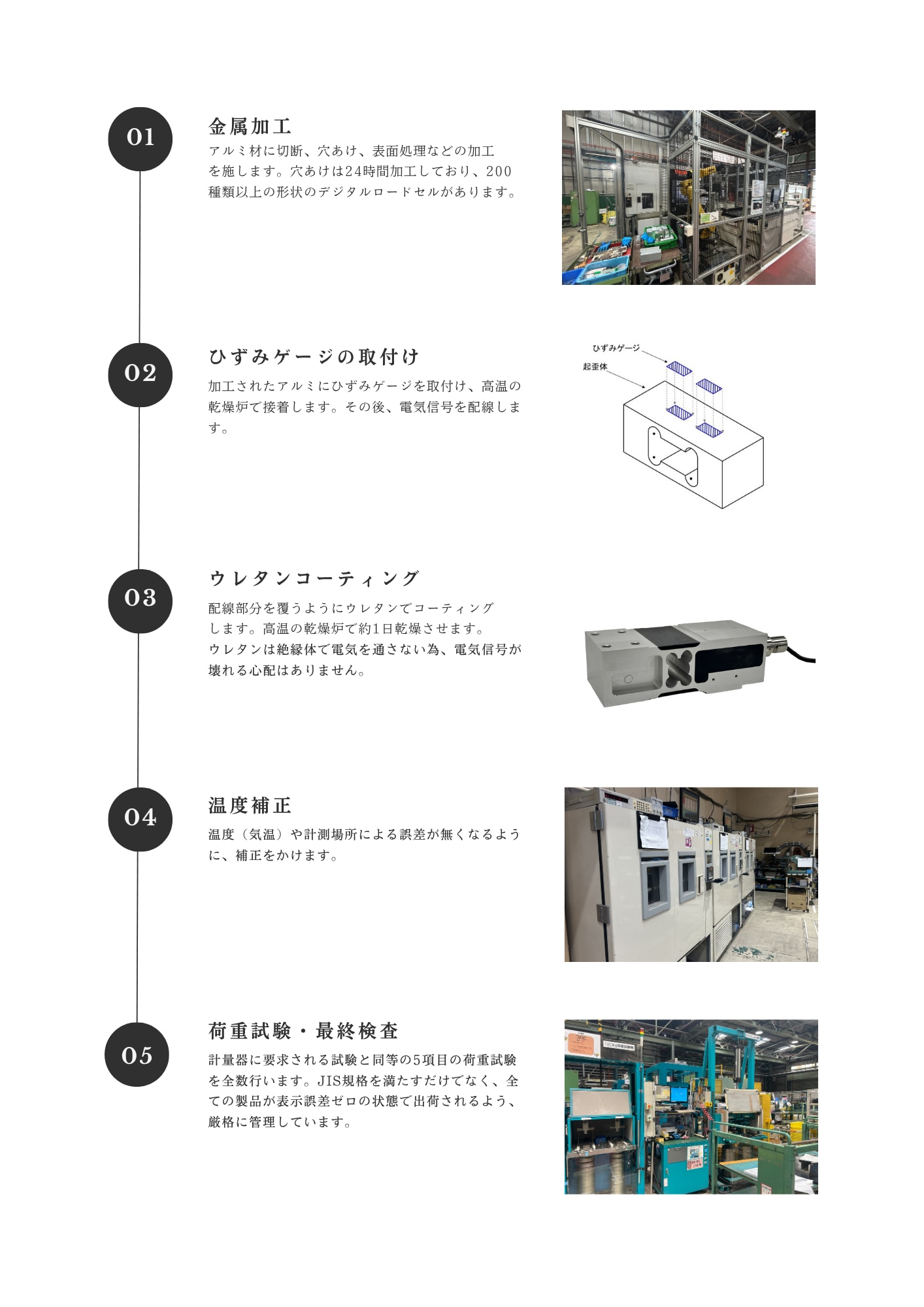

We will introduce the production process in the factory.

All products are inspected according to JIS standards

All manufactured load cells are inspected to the standards required for weighing instruments, ensuring that all load cells meet the same strict requirements as weighing instruments, achieving high reliability.

Not only do we meet JIS standards, but we also strictly manage all products to ensure they are shipped with zero display error.

Inspection at delivery site by service technician

When measuring the same mass in Okinawa and Hokkaido, there will be a slight difference. Just as weight changes on the Moon and Earth, gravity on Earth also shows different values depending on latitude and altitude.

For this reason, Kubota makes corrections before shipping, and after shipping, service technicians make adjustments.

① Before shipping, specify the delivery address and correct the load cell taking into account the gravitational acceleration.

② After shipping, when installation is complete, a service technician will visit the delivery location to check and adjust the measurement values.

By carrying out checks like this, we are able to measure correct values at filling stations across the country.

What are the guidelines and timing for considering updating your LPG filling machine?

Are you wondering when it's time to update your LPG filling machine? Here we'll explain the guidelines and timing for considering an update.

Check out these places!

If your equipment is more than 15 years old, we recommend that you consider updating it.

LPG filling machines contain electronic components that tend to have a shorter lifespan than other components. As a result, it may become difficult to obtain replacement parts over time.

To ensure stable and continuous filling operations, please consider updating your equipment in a planned manner.

Introducing the new, more advanced "Resin-filled Explosion-proof Digital Load Cell"

Kubota has further developed the load cell technology it has cultivated over many years, and has developed a new type of "resin-filled explosion-proof digital load cell." This load cell is an innovative product that is lightweight, highly accurate, waterproof, and explosion-proof.

What are the differences and advantages compared to conventional load cells?

Lightweight and compact

The product weight is 70% less than that of pressure-resistant, explosion-proof load cells (compared to Kubota's conventional models).

Scales equipped with load cells can also be made lightweight and compact.

High precision

The accuracy (limit at which performance is guaranteed) of the pressure-resistant explosion-proof load cells previously used in LPG filling machines was 1/3000, whereas the resin-filled explosion-proof digital load cell is capable of measuring to an accuracy of 1/6000.

waterproof

While pressure-resistant explosion-proof load cells have a structure with gaps inside, resin-filled explosion-proof digital load cells are covered with urethane resin (insulator) all the way to the circuit board, improving waterproof performance.

safety

During the production process, we check every product to make sure there are no air bubbles in the urethane resin.

Introducing the latest LPG filling machine "S-EA-IV" | A next-generation filling machine that combines safety and precision

The latest model of LP gas filling machine "S-EA-IV" is equipped with a "resin-filled explosion-proof digital load cell" and has improved waterproof performance of the weighing platform compared to conventional pressure-resistant explosion-proof models. In addition to the evolution of the load cell's performance, it has also been updated based on customer feedback and comes with a full range of optional functions.

New functions responding to feedback from the field

① Full color LCD display

② Thin base Shortening construction period

③ Check filling history is possible

④Switching between online and offline modes is easy

⑤Indicator water sprinkler cover (optional)

⑥ Display cylinder for checking filling status (optional)

Other useful features include the ability to directly register cylinder information, which can be used in conjunction with a new filling management system.

For specifications and detailed information on the latest LP gas filling machine "S-EA-IV"Product PageIt is stated in.

View product page≫≫

summary

UNIDACK filling machines achieve accurate filling thanks to high-precision load cells and thorough quality control. The latest model, "S-EA-IV," is equipped with a "resin-filled explosion-proof load cell," further improving safety and maintainability. By considering upgrading from your previous model, you can expect to see improvements in the efficiency and safety of your LPG filling operations.