A thorough explanation of the structure and mechanism of the drying oven | The secret to stabilizing quality

Have you ever wondered which drying oven to choose when installing new equipment? Drying ovens are important equipment that greatly influences product quality.

This article will provide a wide range of information, from the basic role of drying ovens to the different types such as gas, batch, and hot air circulation, temperature control technology for stabilizing quality, and how to select the best oven for your application.

Table of contents [hidden]

- 1.What is a drying oven?

- 2.What is a gas drying oven?

- 2.1.Structure and mechanism of gas drying ovens

- 2.1.1.LPG heating method

- 2.1.2.LNG-based heating method

- 2.2.Types and features of burners

- 2.2.1.Gun-type burner

- 2.2.2.Duct-type burner

- 3.Whatis a hot air circulation drying oven?

- 3.1.Structure and mechanism of hot air circulation drying oven

- 3.1.1.Heat uniformity using a circulation fan

- 3.1.2.Program-controlled temperature control

- 3.1.3.Methodsfor reducing heat loss

- 3.2.Structure and Use of Paint Drying Oven

- 4.Construction track record

- 5.Selection and introduction points of drying oven

- 6.Summary_

What is a drying oven?

We will explain the basic definition of a drying oven and its functions.

Let's take a closer look at the basic role and importance of drying ovens as industrial furnaces to gain a deeper understanding of them.

The role of the drying oven

A drying oven is a device that heats parts and materials to remove solvents and moisture contained in them. While you might imagine it simply as a way to "dry," its role is quite diverse.

role | 01 |

Improved durability and appearance quality

Quality can be improved by curing the coating on painted products at the appropriate temperature and time.

role | 02 |

Drain and dry

Completely removing any water droplets remaining after cleaning metal parts prevents rust and reduces defects in subsequent processes.

role | 03 |

Annealing

This process removes internal distortion that occurs during molding in the manufacturing process of plastic parts. A dedicated heat treatment furnace may be used, but a drying furnace is often used to achieve the same effect.

The importance of drying ovens

The drying process is a critical step that determines durability, appearance, and performance. If this process is not done properly, the quality of the final product may not be fully realized, no matter how excellent the materials or processing techniques used.

Furthermore, the efficiency of the drying process directly affects the overall production lead time and manufacturing costs. For example, if the drying time is too long, production efficiency will decrease and energy costs will increase. Conversely, if the drying is insufficient, defective products will be produced and reprocessing will be required, leading to further costs and time losses.

What is a gas drying oven?

A gas drying oven is a device that uses fuels such as LPG(liquefied petroleum gas) orLNG(liquefied natural gas) to generate hot air to dry workpieces.

Structure and mechanism of gas drying oven

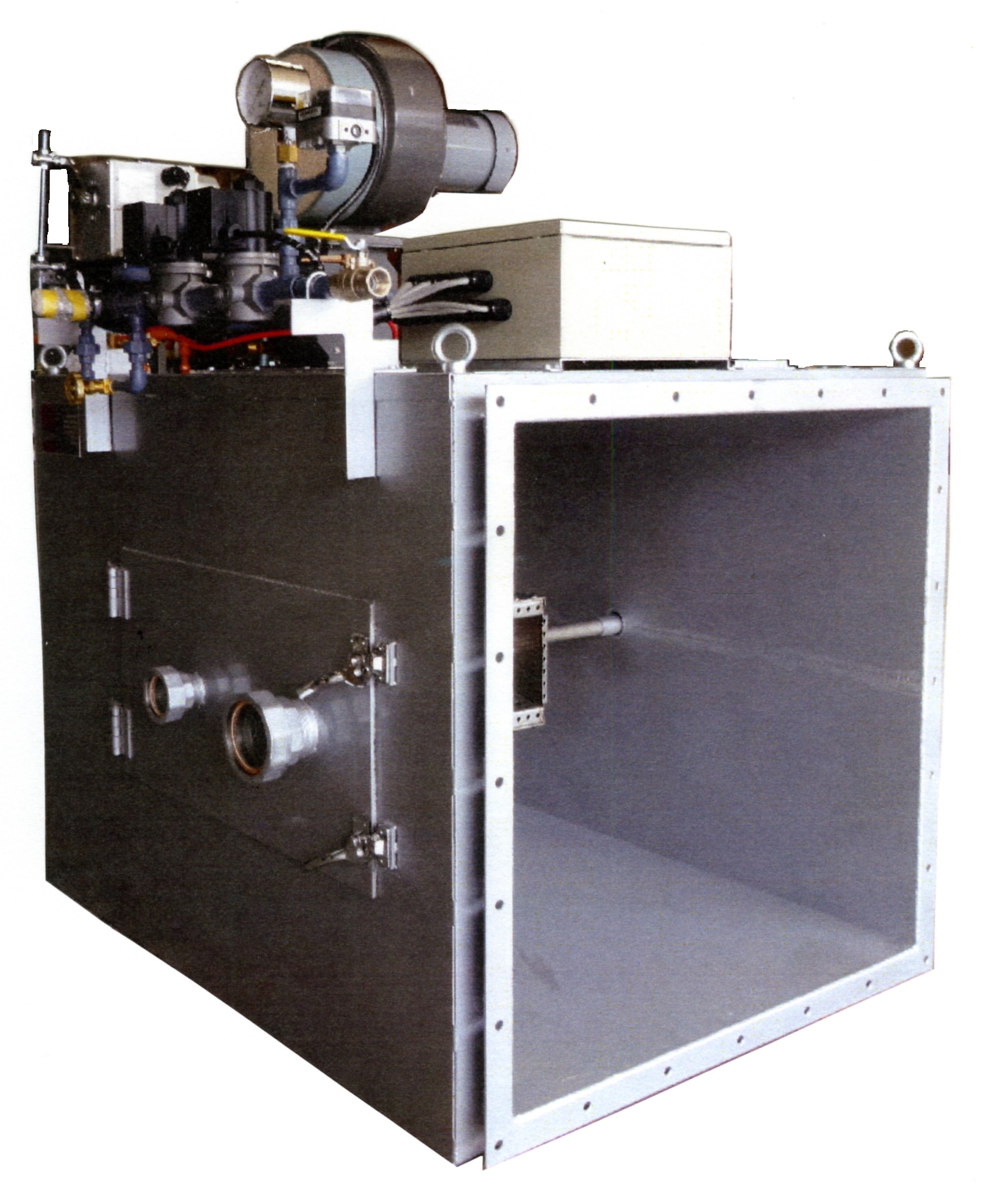

A gas drying oven mainly consists of the oven body (chamber), a gas burner as a heat source, a circulation fan to circulate the air inside the oven, and an exhaust duct to discharge the combustion gases.

The most commonly used heating method is the direct heating method, in which hot air generated by a burner is supplied directly into the oven. This method has the advantage of being highly thermally efficient, and is particularly widely used for drying metal workpieces. In addition, by combining it with the hot air circulation method, it is possible to maintain a uniform temperature inside the oven and dry the entire workpiece evenly.

Batch-type drying ovens are particularly effective for small-lot, high-mix production or for processing workpieces with different drying conditions in sequence. However, because the temperature inside the oven drops when workpieces are loaded and unloaded, they are not suitable for continuous production.

LPG heating system

LPG(liquefied petroleum gas)is widely used as fuel for gas drying ovens.

LPGis supplied in cylinders or small storage tanks, so it has the great advantage of being relatively easy to install even in places where city gas piping infrastructure is not in place. For this reason, it tends to be chosen at sites where flexible operation is required, such as when introducing drying ovens due to changes in the layout or expansion of a factory, or for use on temporary production lines.

Furthermore,LPGhas a relatively stable supply even in the event of a disaster, whichis advantageous from the perspective of business continuity planning (BCP), as it allows production to continue even in the unlikely event of an emergency. Drying furnaces that use LPGare used at many manufacturing sites due to their ease of installation and stable supply.

LNG-based heating system

Along with LPG, LNG(liquefied natural gas) isthe main fuel for gas-fired drying furnaces.

LNGis often used primarily as city gas, and it is assumed that the installation site has a city gas piping infrastructure in place. Once the piping is installed, the fuel supply is stable and there is no need to change cylinders, which gives it an advantage in terms of operational efficiency in large-scale production lines and drying ovens that require continuous operation.

LNGalso has the environmental advantage of producing lessCO2when burned thanLPG, which can contribute to reducing the environmental impact, making it a very attractive option when considering corporate efforts to achieve the SDGsand compliance with environmental regulations.

Burner types and features

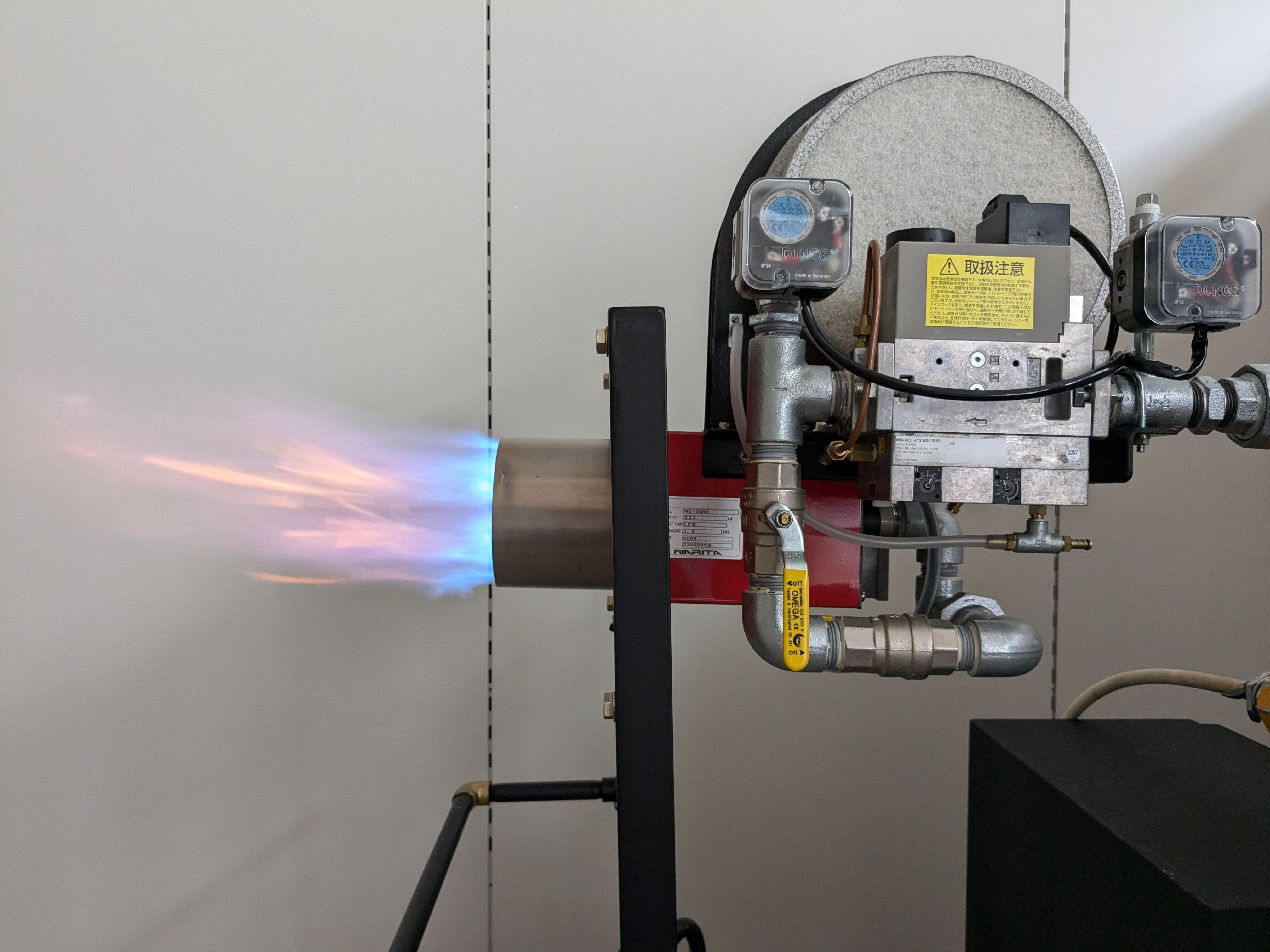

The "burner," which can be said to be the heart of a gas drying oven, is an important device that efficiently mixes and burns fuel and air to generate the thermal energy needed for drying. Here, we will take a closer look at thetwotypes of burners commonly used in gas drying ovens, the "gun-type burner" and the "duct-type burner," and their respective features and how they affect drying.

GaType Bner

Gun-type burners have an integrated combustion unit and are compact in shape. Many of them use an injection method (nozzle mix method) in which fuel gas and combustion air are mixed in a nozzle and burned.

- Features and Benefits

①It has excellent ignition properties and is suitable forshort start-up times and repeated ON/OFF operation cycles.

②The structure is relatively simple and maintenance is easy.

3) Effective for relatively small drying ovens and applications where cost performance is important.

Gun-type burners are mainly used in small to medium-sized drying ovens, and most of the types on the market are of the injection type.On the other hand, there are also gun-type burners that use the premix method, in which fuel and air are mixed beforehand inside the burner, and these are sometimes used in large ovens or for applications requiring particularly high temperature accuracy.

Duct Type Burner

Duct type burners are installed directly inside the duct that circulates hot air, and many of them use the semi-nozzle mix method, which mixes fuel and air and burns them.The main features and advantages of these burners are as follows:

- Features and Benefits

(1) By burning fuel in the air flowing through the duct, hot air with a uniform temperature and a wide temperature range can be generated.

②It is easier to maintain a uniform temperature distribution throughout the furnace, minimizing the impact of temperature variations on product quality.

3. Demonstrates excellent performance in large drying ovens, paint drying lines where high temperature uniformity is required, and heat treatment of precision parts.

4. Uniform drying and hardening contributes to stabilizing quality, reducing unevenness in the finish, improving yield, and improving production efficiency.

What is a hot air circulation drying oven?

Here, we will focus on the mechanism of "hot air circulation," which has a major impact on drying quality. The hot air circulation method is the most common solution to the issue of how to maintain a uniform temperature inside the oven. We will explain in detail, step by step, from an overview to the specific mechanism for achieving uniform heating that eliminates temperature variations, and even ways to save energy.

Structure and mechanism of hot air circulation drying oven

The hot air circulation method is a heating method that keeps the temperature almost uniform by forcibly circulating heated air inside the drying oven with a circulation fan throughout the oven. Rather than simply heating the air with a burner or heater, the oven is designed to constantly circulate the hot air inside the oven so that heat is transferred evenly to every part of the workpiece.

Unlike natural convection systems, this prevents temperature stratification, where hot air rises and cold air falls, and makes it possible to maintain the entire oven at a stable temperature close to the set point. This prevents uneven temperatures, which directly affect product quality, and ensures uniform drying and curing.

Heat uniformity achieved by circulation fan

In the hot air circulation system, the "circulation fan" plays the most important role in achieving uniform heating inside the furnace.

The fan draws in hot air from inside the furnace, passes it through the heater and burner, and then blows it back into the furnace, creating a constant air flow. Whether the fan's installation position, air volume, and air speed are properly designed has a significant impact on heat uniformity.

Furthermore, parts called "baffles" are placed inside the furnace to distribute and control the flow of hot air, thereby evenly transferring heat to areas in the shadow of the workpiece and areas where heat tends to stagnate. This minimizes the temperature difference between the top and bottom of the furnace, and between the entrance and the back, and is designed to ensure that the workpiece follows roughly the same temperature history no matter where it is placed.

Program-controlled temperature control

The program control system allows for "programmed operation," which automatically controls a series of temperature changes, such as increasing the temperature, maintaining it for a certain period of time, and then decreasing the temperature, along a set time axis. This function makes it possible to reproduce complex drying profiles, ensuring stable drying quality without human intervention.

The control panel centrally manages the control circuits for major equipment such as drying temperature, time, burners, heaters, circulation fans, etc. In particular, time proportional control (a type of PIDcontrol) detects the deviation of the current temperature from the target temperature in real time and fine-tunes the amount of heat, minimizing temperature fluctuations (hunting) and maintaining an extremely stable temperature.

How to reduce heat loss

To improve the energy efficiency of drying ovens and reduce operating costs, it is important to reduce heat loss.

One typical mechanism for achieving this is the insulation structure of the furnace body. High-quality insulation is used for the furnace walls and ceiling, and its thickness is optimized to match the furnace's maximum operating temperature. This prevents heat from escaping from the furnace to the outside, reducing unnecessary energy consumption. Door sealing is also essential for reducing heat loss. High-performance sealing materials and multi-layered doors minimize heat leakage through gaps in the doors. Furthermore, to prevent heat loss from openings such as workpiece loading/unloading openings and exhaust ducts, air curtains are sometimes installed, and exhaust heat recovery systems are sometimes introduced to recover exhaust heat and use it to supply air or preheat the furnace.

These "environmentally conscious designs" not only contribute to energy conservation, but also to reducing CO2emissions throughout the factory, realizing sustainable production activities.

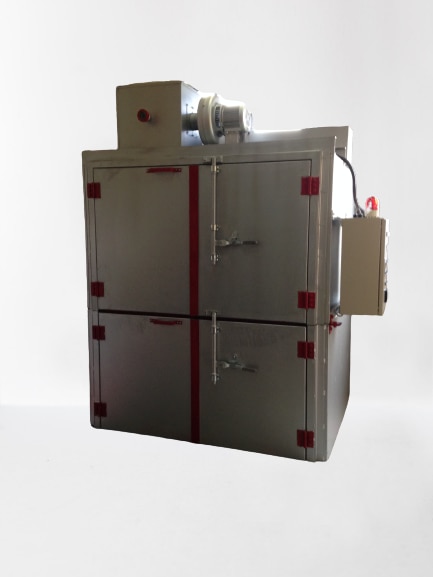

Structure and uses of paint drying ovens

Among the many uses for drying ovens, "paint drying" places particularly high demands on quality.

Unlike general drying ovens, paint drying ovens are designed to meet specific requirements directly related to coating quality, such as uniform curing of the paint film, prevention of color unevenness, and proper discharge of solvents. For this reason, the cleanliness of the oven is extremely important, and air purification is provided using an air intake filter to prevent the intrusion of dust and dirt from outside. Furthermore, because the solvents contained in paint are volatile organic compounds (VOCs), an exhaust system is essential to safely and reliably discharge these outside the oven. In some cases, deodorizing equipment and heat recovery equipment are also installed to neutralizethe VOCsin the exhaust gas.

The importance of drying in the painting process

"Drying" in the painting process is not just a matter of removing moisture, but is an extremely important process that determines the functionality, durability, and aesthetics of the product.

Proper drying allows the solvent to evaporate and the paint to harden and demonstrate its intended performance. However, if drying is incomplete or the temperature or time is incorrect, quality problems such as peeling, scratches, uneven color, and blistering can occur, significantly reducing the reliability of the product. For this reason, paint drying is an essential process for ensuring product quality.

Temperature control technology for paint drying ovens

Advanced temperature control according to the type of paint and workpiece characteristics is essential for paint drying ovens. The optimal heating curve, baking temperature, and holding time vary depending on the paint. In particular, with solvent-based paints, gradual solvent evaporation through "pre-drying"is important for maintaining the quality of the paint film.

Construction track record

Click to enlarge image.

Selection and introduction points of drying oven

There are several important steps to take to ensure a successful oven selection and installation.

POINT | 01 |

Clarification of workpiece characteristics and drying purpose

By clarifying the material, shape, size, and drying purpose (moisture removal, coating effect, distortion removal, etc.), it is possible to determine whether to use a batch or continuous method and the required temperature profile.

POINT | 02 |

Comparison of heat sources and heating methods

We understand the characteristics of gas heaters such as LPG and LNG, electric heaters, and far-infrared heaters, and make a comprehensive judgment on running costs, installation environment, and required temperature range.

POINT | 03 |

Selection of reliable manufacturers

Choosing a manufacturer with solid technical capabilities, customization capabilities, and after-sales support will lead to long-term stable operation and quality maintenance.

summary

In this article, we have explained the following points that will be useful in selecting a drying oven.

- The basic role of the drying oven

- Drying oven type (gas type, hot air circulation type)

- Temperature control technology to stabilize quality

- Structure and uses of paint drying ovens

- Key points for selecting a drying oven

If you are having trouble selecting a drying oven or gas burner, please feel free to contact Daido Kogyo.

Our knowledgeable staff will help you select the best burner and drying furnace for your company!