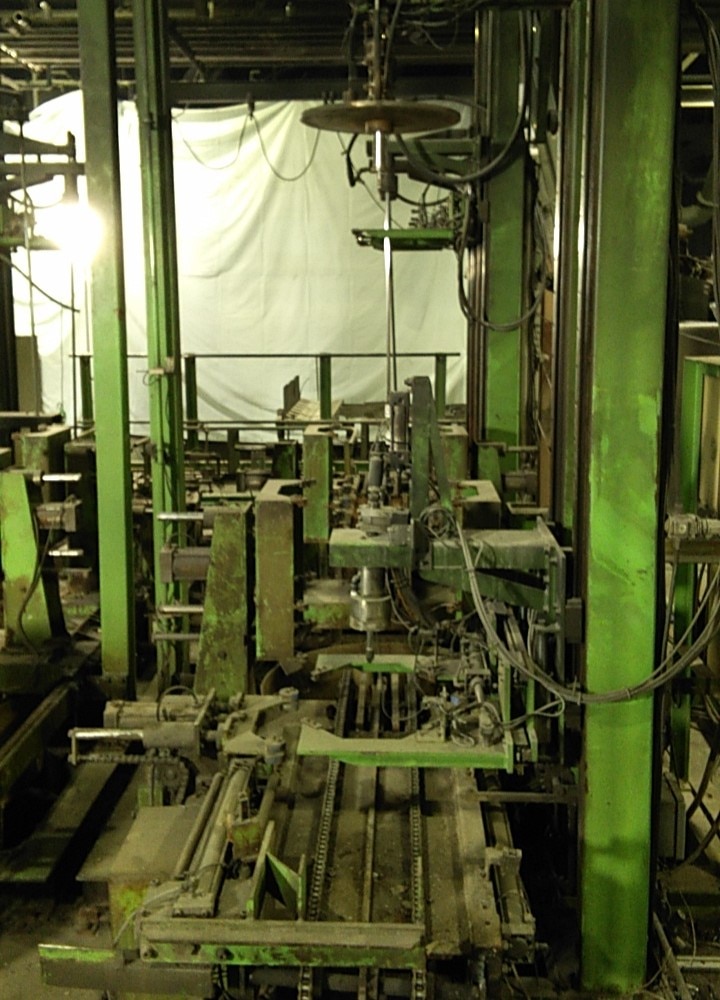

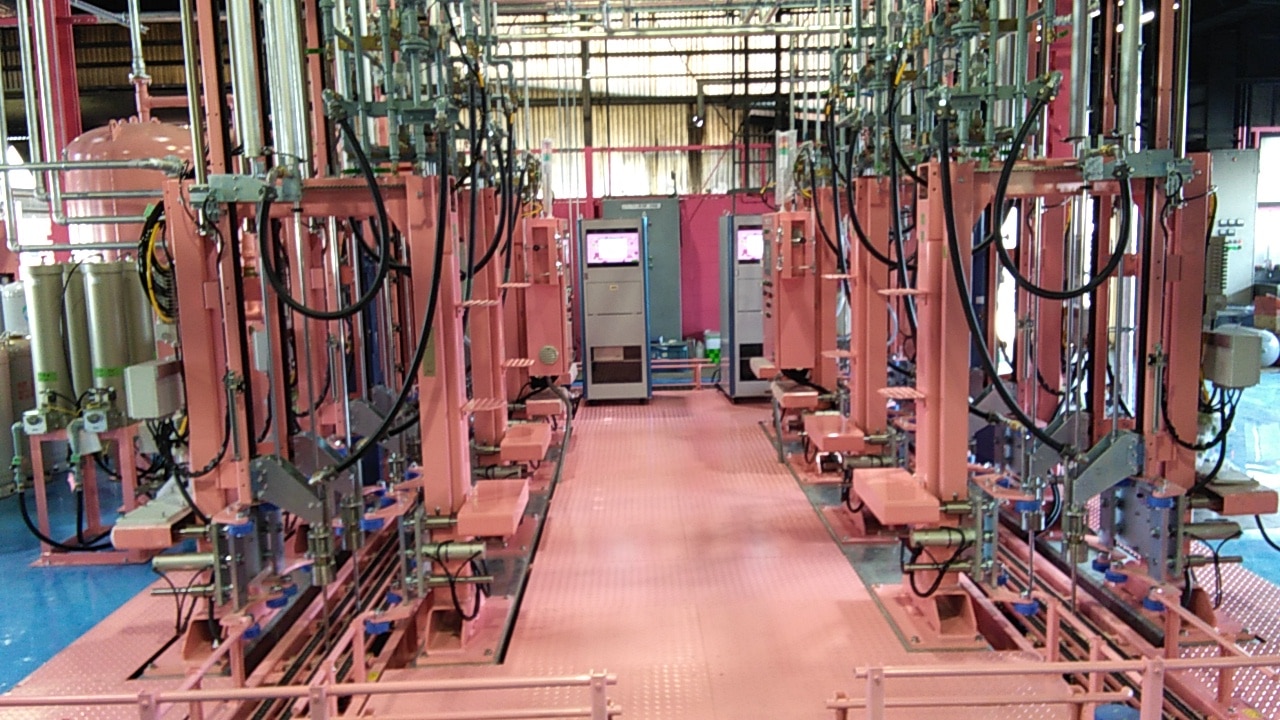

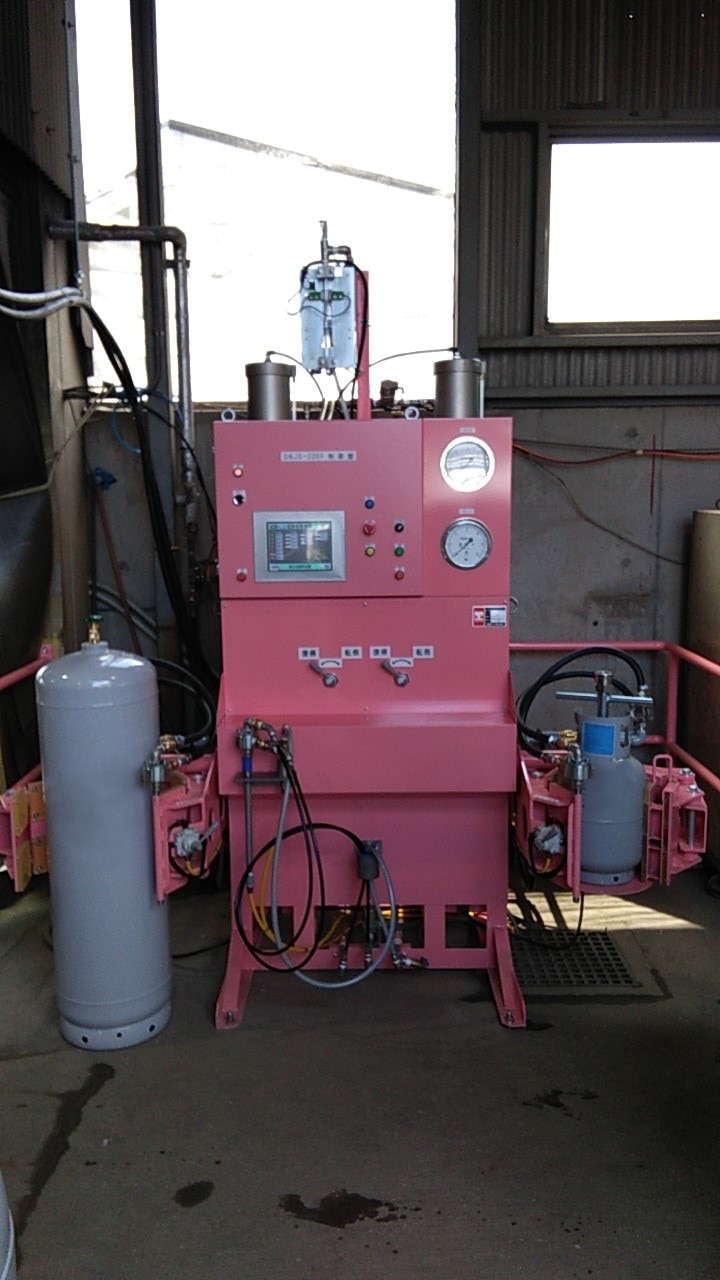

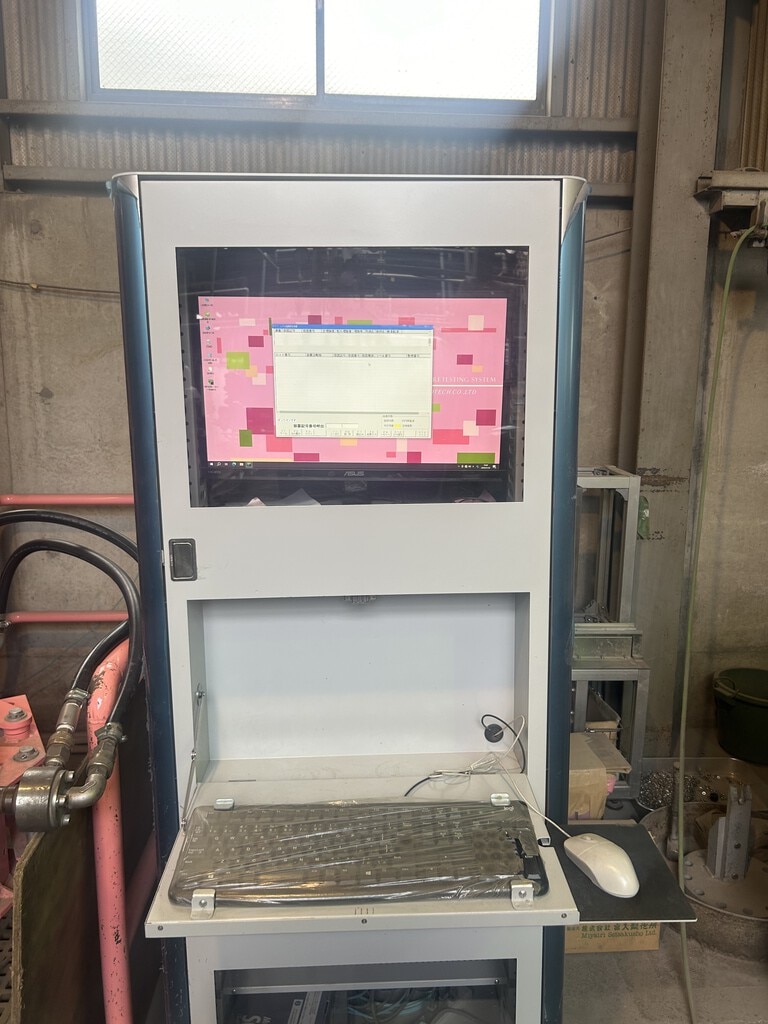

The efficiency of the equipment can be seen in more ways than just increasing the number of bottles processed. Before the upgrade, workers had to check which process cylinder was in (water injection, pressure test, drainage, drying) and move to each process location to operate the switch to start the process. After the upgrade, once the system was started, there was no need to operate each process, and workers had to move around and check things less. In addition, the control panel display clearly shows the work process, making it easy for foreign technical intern trainees to operate. After the upgrade, workers were seen to be more proactive in their work, and it seems that the company's overall problem of lagging behind in training is also moving in the direction of improvement.

In addition, with this new system, we now receive data such as the stamp numbers and tare weights of all cylinder from our customers and register them all at once in the system. As a result, we no longer need to manually register cylinder data one by one, which has led to a significant reduction in overtime hours.