Smooth out the fine bends

Bending accuracy and

We are bender that balances work efficiency with

Kenner Co., Ltd.

Managing Director Keisuke Mori

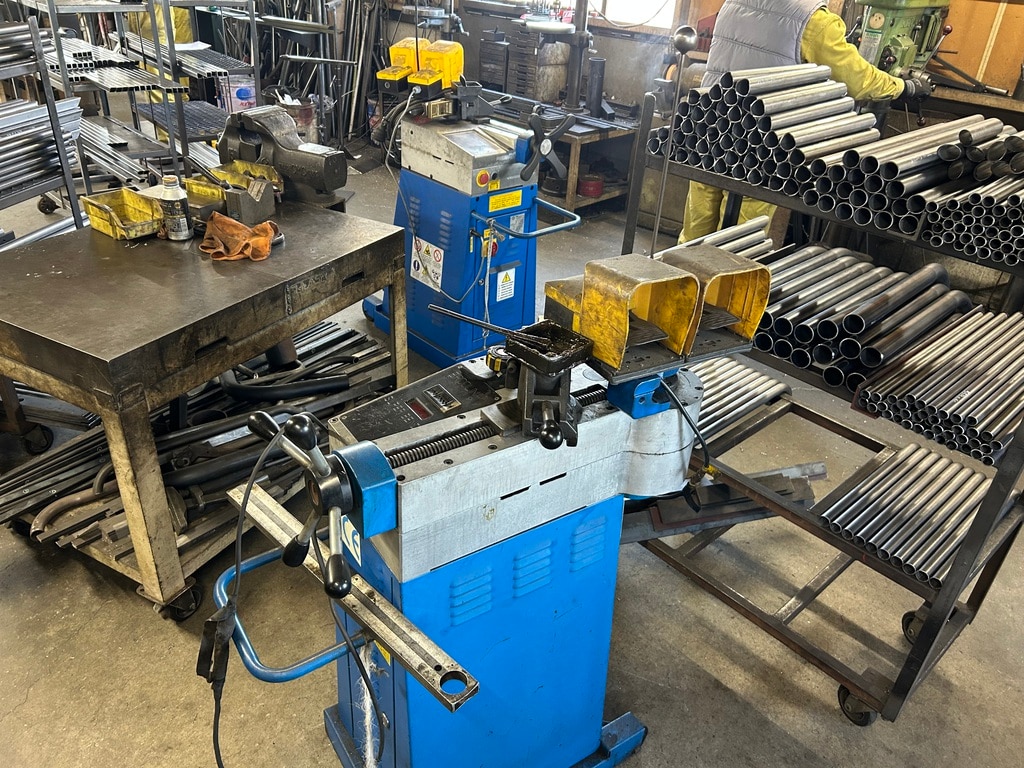

Pipe bender TB-60installation example