Stable quality and flexibility on-site

At Unitwin P

I am able to balance both

Tsukamoto Tekkin Co., Ltd.

Representative Director Yoshinori Tsukamoto

Unitwin Pinstallation example

Tsukamoto Tekkin Co., Ltd.

Representative Director Yoshinori Tsukamoto

Unitwin Pinstallation example

Company name

Tsukamoto Tekkin Co., Ltd.

location

〒849-0936

2029-12 Morita, Nabeshima-cho, Saga City, Saga Prefecture

Number of Employees

15 people

Business content

Reinforcement work

Introduction products

Unitwin P

URL

https://tsukamoto-tekkin.co.jp

the purpose

- Welding to the inside of the stirrup bars is expected to improve construction flexibility.

- Actively promoting automation and mechanization in response to the industry's labor shortage and the need to shorten construction periods

assignment

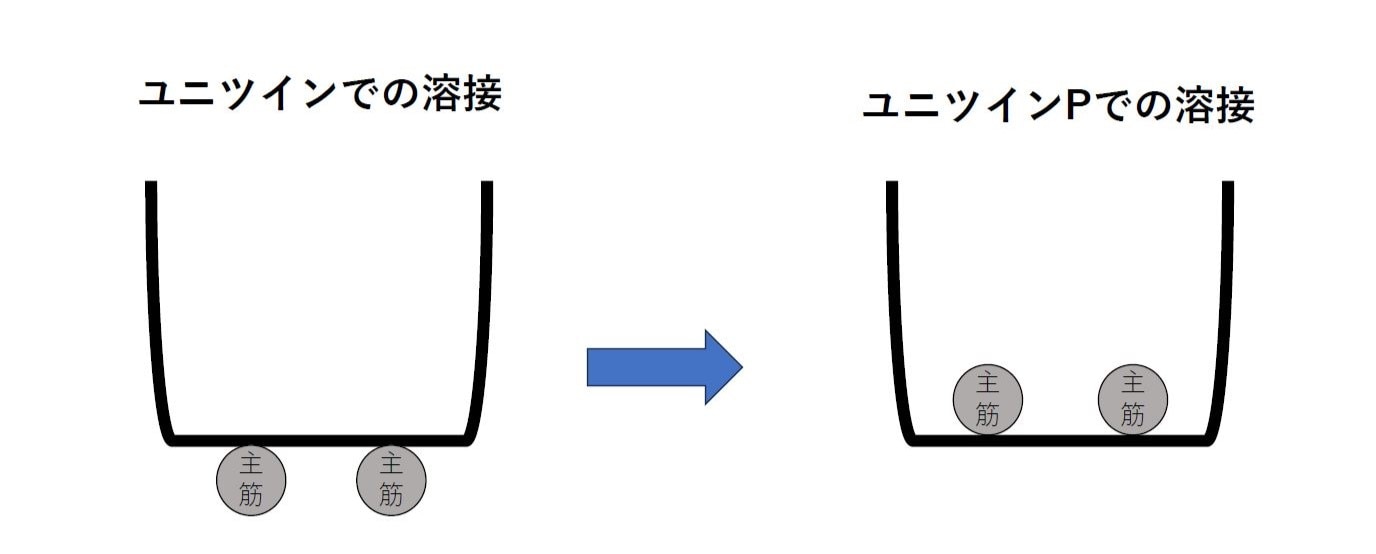

-In conventional machines, stirrups were fixed and welded facing upwards,which restricted their placement.

effect

-Itis now possible to accommodate assembly methods that were previously impossible,broadening the scope of construction.

-By switching from two-point simultaneous welding to sequential welding, warping and twisting of the main reinforcement bars has been reduced.

Click here for detailed specifications of Unitwin P

Tsukamoto Steel Works Co., Ltd.

Address: 2029-12 Morita, Nabeshima-cho, Saga City, Saga Prefecture, 849-0936

TEL 0952-32-1077

URLhttps://tsukamoto-tekkin.co.jp

Toyo Construction Machinery Co., Ltd. Fukuoka Sales Department

Address: 21-28-5 Matsushima, Higashi-ku, Fukuoka City, Fukuoka Prefecture, 813-0062

TEL 092-621-6093

URL https://www.toyokensetsukohki.co.jp