Faster handrail production

By bending

Achieving beauty and efficiency

Kumai Co., Ltd.

Ryosuke Kumai, Managing Director

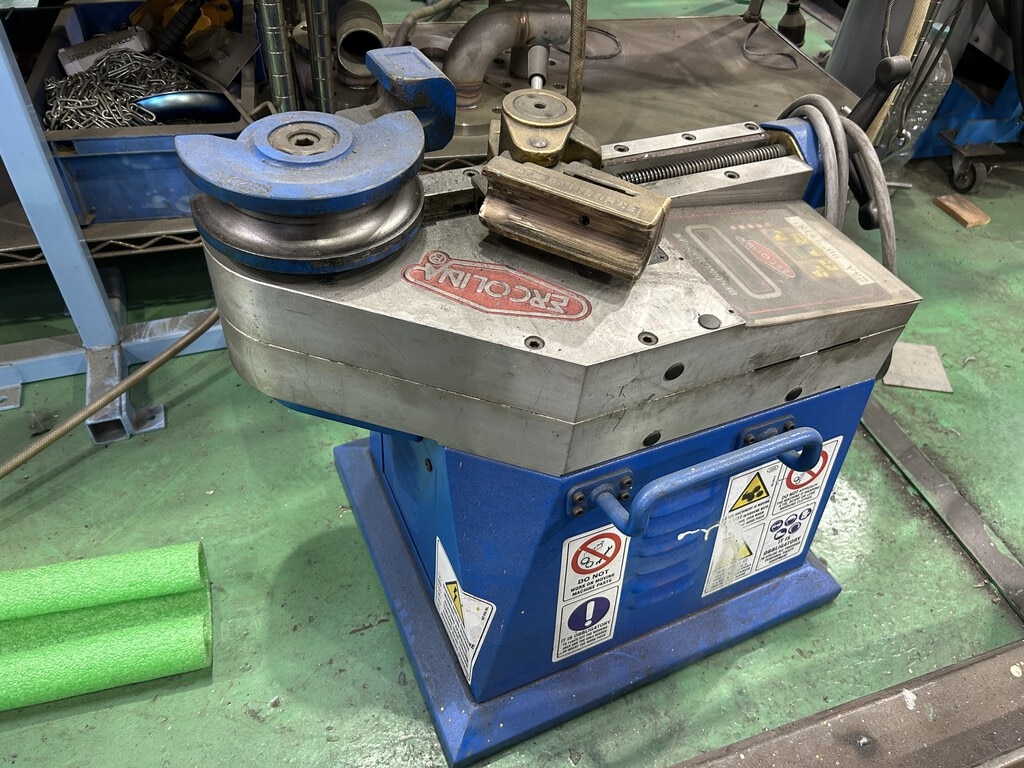

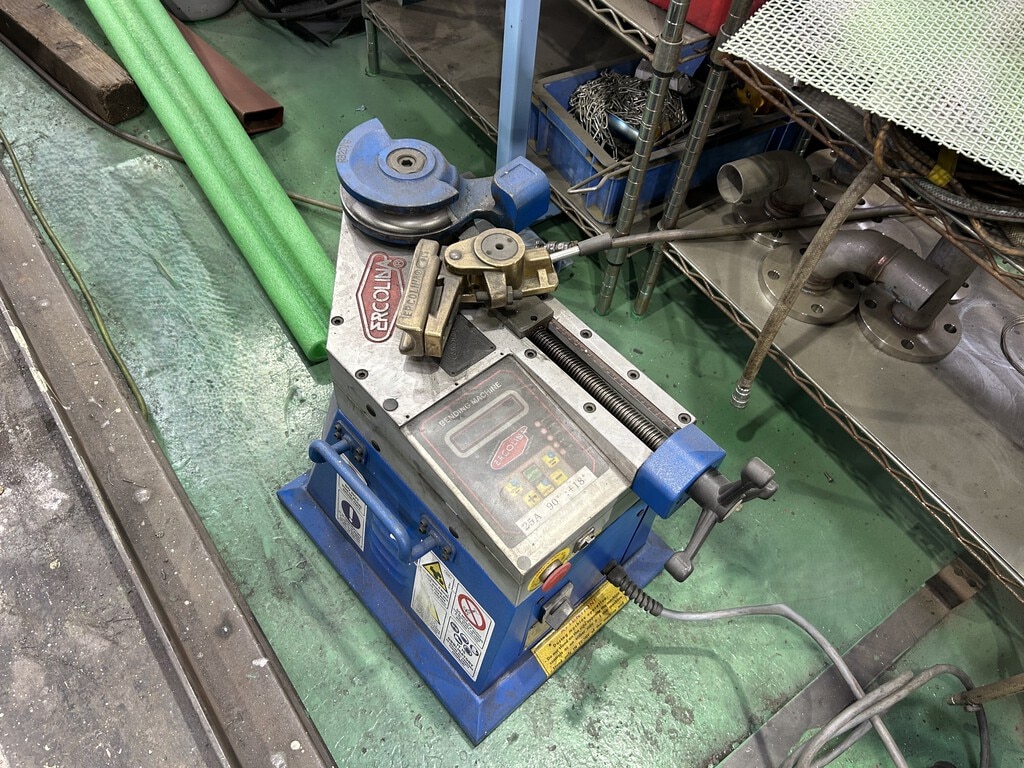

Pipe bender MB42Pinstallation example

Kumai Co., Ltd.

Ryosuke Kumai, Managing Director

Pipe bender MB42Pinstallation example

Company name

Kumai Co., Ltd.

location

〒252-1125

3-4-19 Yoshioka Higashi, Ayase City, Kanagawa Prefecture

Number of Employees

15 people

Business content

Manufacture and installation of painting plant equipment

Introduction products

Pipe bender MB42P

URL

https://kuma-i.co.jp

the purpose

-Improved efficiency in manufacturinghandrails installed in painting plant facilities

- Improved aesthetics by changing from welding to bending

assignment

-Traditionally,handrails were manufactured using welded elbows, which requireda lot of man-hoursfor preparation, welding, and finishing.

-In a factory with large products and machinesSecuring work space

effect

-Work time reduced to approximately one-fourth, significantly improving work efficiency

-By manufacturing using pipe bending,No joints, eliminating uneven paint

- The main body iscompact and portable, allowing for effective use of work space

Click here for detailed specifications of the pipe bender

Kumai Co., Ltd.

Address: 3-4-19 Yoshioka Higashi, Ayase City, Kanagawa Prefecture, 252-1125

TEL 0467-80-2852

URL:https://kuma-i.co.jp