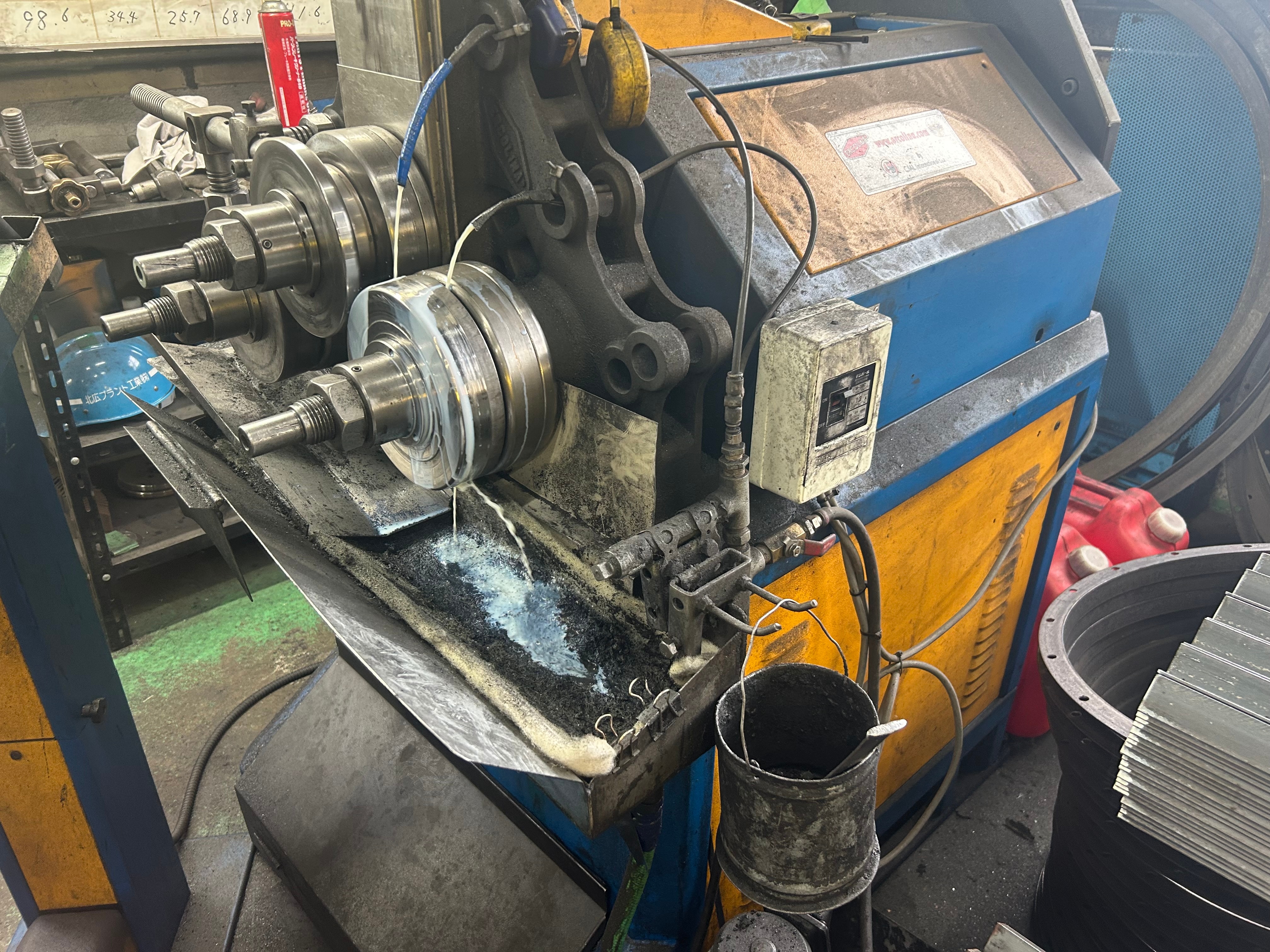

The reason why Kitahiro Plant Industries Co., Ltd. introduced the Ring Roller bender was that they wanted to realize in-house production of "round angle flanges," a type of duct piping part.

Before the introduction of the system, the company purchased ready-made products from external suppliers, but in many cases, it was unable to flexibly meet customer requests such as "I want delivery on the day of the order" with ready-made products.

In order to respond to these needs quickly and reliably, the company decided to bring part of the manufacturing process in-house.