Kuroda Steel Pipe Co., Ltd., which is particular about the quality of its cutting processing, had been using a deburring machine made by another company for some time, and since the equipment was not particularly outdated, they did not initially have any plans to update it.

However, when we proposed a new cutting machine, we also proposed the introduction of a deburring machine and performed an actual demonstration. After the client confirmed the operability of the machine and the precision of the finish on the spot, they expressed their expectations for improved work efficiency and decided to introduce it.

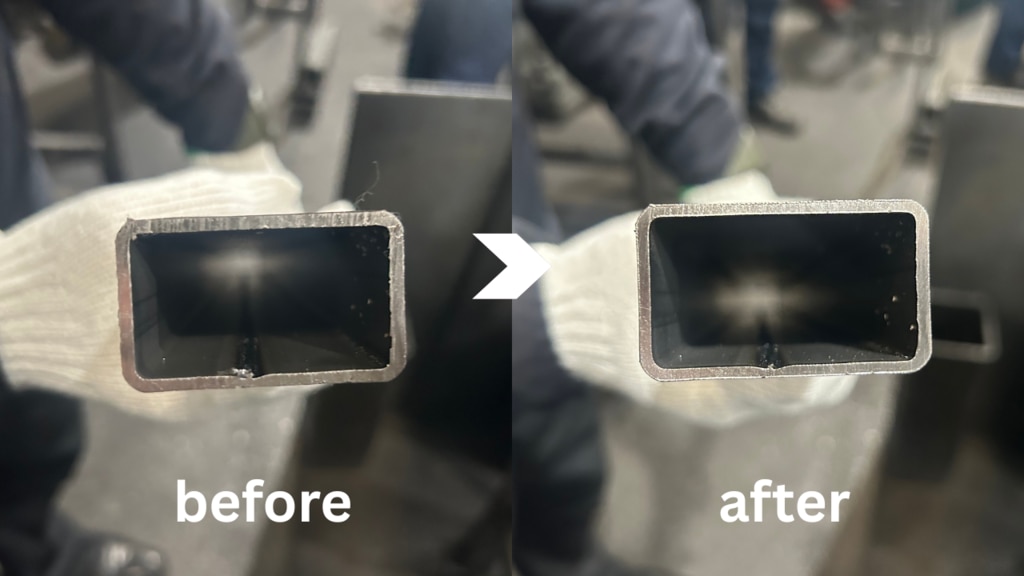

Conventional deburring machines only have a brush that rotates in one direction, and it is necessary to change the angle of the steel material while working, which makes it time-consuming to remove burrs and burrs from various angles of steel material and inside and outside of pipes. In contrast, our deburring machine supports two-axis rotation, so it can remove burrs from inside and outside at the same time, eliminating the need to switch between the top and bottom. This difference is a point that has been highly praised by workers on site.