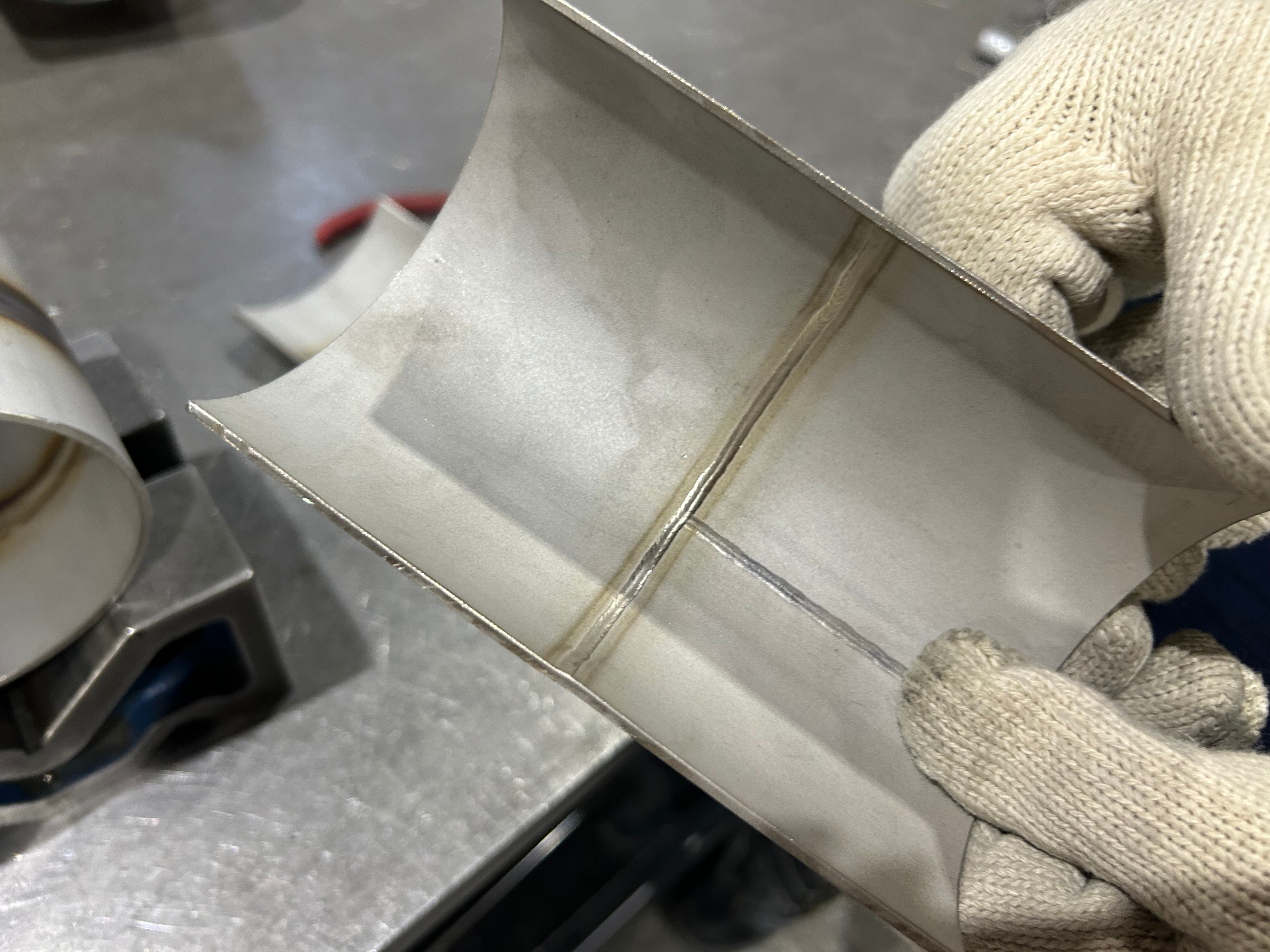

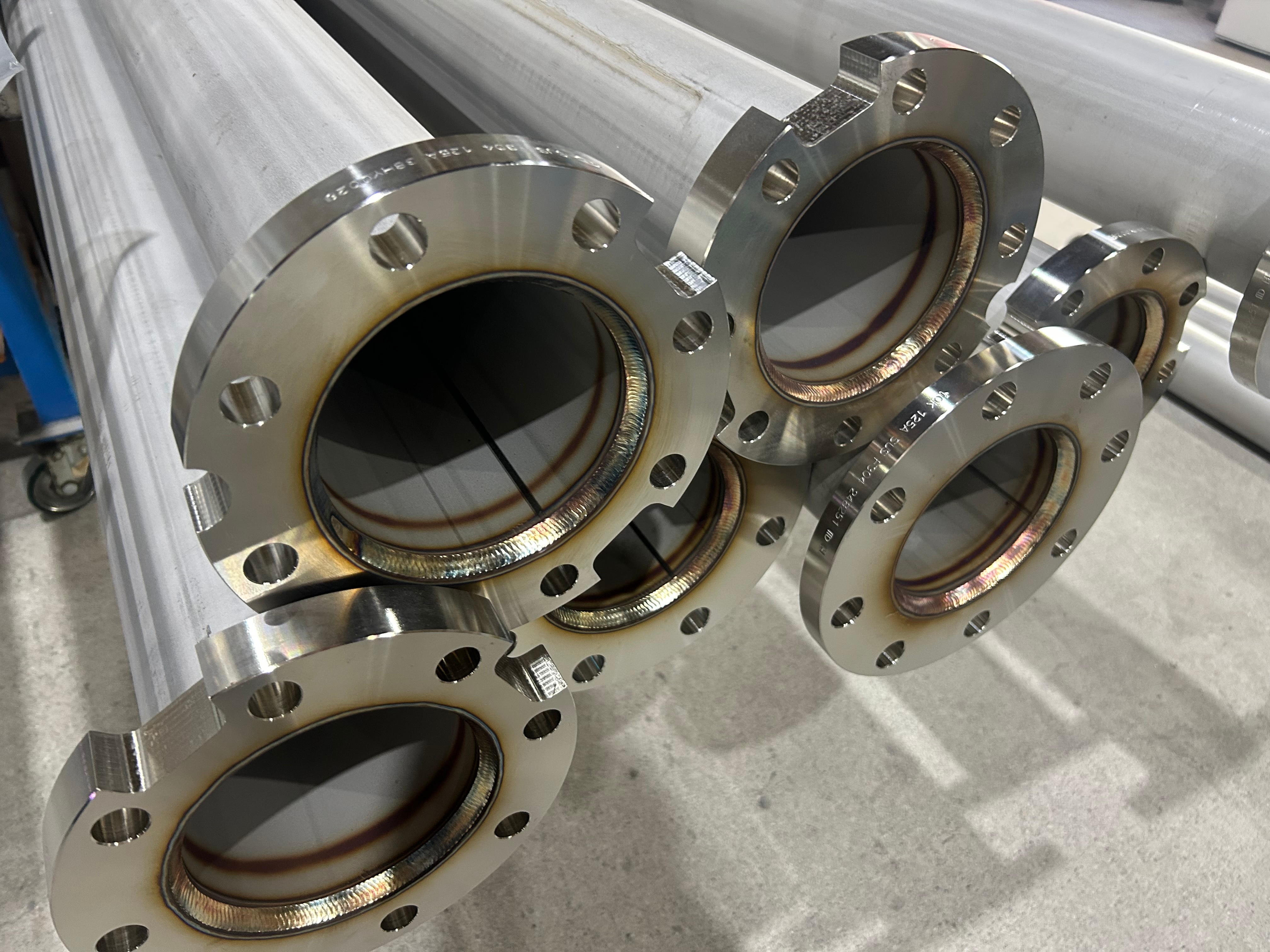

By introducing the rotary cutting machine, the company has experienced the benefits of improved cutting precision and work stability. In particular, the high cutting precision, which is sufficient to handle butt welding of thin-walled stainless steel pipes, is a point that has earned the company great trust on-site. With a band saw, cutting surface often becomes slanted or burrs appear, requiring additional processing before welding, but the rotary cutting machine achieves a finish that is ready for welding as is.

The excellent design is also highly rated in terms of safety. The blade rotates in the opposite direction to that of ordinary products, so chips generated during cutting are less likely to fly towards the worker, and the structure allows for safe work without obstructing visibility or the working environment.

Another major benefit is that it requires no strength to operate, so anyone can perform the work with consistent quality regardless of experience or physique. This eliminates the dependency of work on individuals, improving productivity and reproducibility across the entire site.