Integrated production x latest equipment

With stud welding

To gain even greater trust

Kyoshin Co., Ltd.

Managing Director Susumu Tsujimoto

CD stud welding machine installation example

Kyoshin Co., Ltd.

Managing Director Susumu Tsujimoto

CD stud welding machine installation example

Company name

Kyoshin Co., Ltd.

location

〒574-0064

3-12-57 Goryo, Daito City, Osaka Prefecture

Number of employees

70 people

Business content

General sheet metal processing, precision sheet metal processing,

Can manufacturing, machining

Products introduced

CD stud welding machine

URL

https://www.f-kyo-shin.co.jp

the purpose

- I want to weld bolts stably and with high strength.

-We want to be able to use stud welding on M8 bolts as well, expanding the range of products we can use.

assignment

-With conventional welding machines, there was concern about the stability of the welding gun.

-OnlyM6 bolts could be machined, and M8 bolts had to be welded by hand.

effect

- Welding time is reduced to just a few seconds, improving work efficiency

- M8 bolt welding can now be done by machine, expanding the range of products that can be handled

Click here for detailed specifications of CD stud welding machine

Fiber laser welding machines, etc.

We have a wide range of laser equipment.

Divide into teams to improve the company environment

We are implementing the project and announcing the results.

Manufacturing of training equipment

This product was purchased for the production of ultrasonic cleaning tanks for use in hospitals and other facilities. Since the ultrasonic cleaning tank expands and contracts during use, the bolts to be welded must also be strong enough. The welding machine they had previously used had concerns about the stability of the welding gun. They decided to install this machine in order to further improve product quality by achieving more stable operation.

Furthermore, previous welding machines could only handle bolts up to M6, so bolts larger than that had to be welded manually. The CD stud welding machine introduced this time can also weld M8 bolts, and the fact that it can handle a wider range of products and specifications was one of the major deciding factors in considering its introduction.

Head Office and Factory

Inside the factory (Factory 1)

1. No distortion occurs, improving quality and efficiency

②Improved ability to handle small lots of a wide variety of products

With the previous machine, M8 bolts were welded manually, taking about 1-2 minutes per bolt, but with the introduction of this machine, the time has been significantly reduced to just a few seconds. Furthermore, since no distortion occurs during welding, the quality of the product itself has improved and the labor required for finishing has been reduced.

Recently, there have been cases where customers have been instructed to "attach bolts using stud welding." By introducing the CD stud welding machine, it has become possible to meet this request even with M8 bolts, and customers have commented that "it was a good decision to introduce it."

The workbench was manufactured in-house by Kyoshin Co., Ltd. for ease of use.

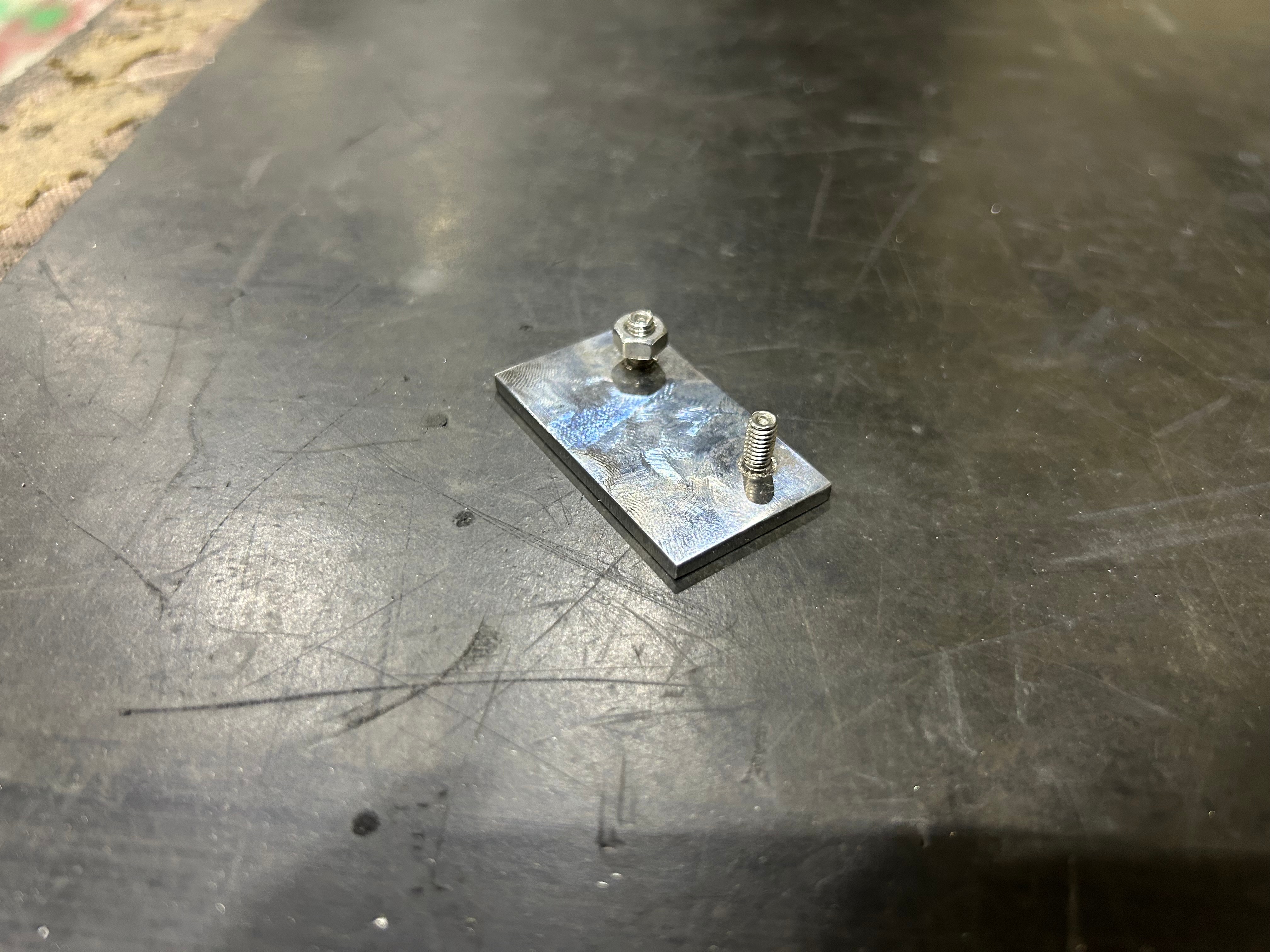

Bolts welded using a CD stud welder

Kyoshin Co., Ltd. aims to increase sales and grow to a company with 100 employees, and will continue to invest in equipment and improve the working environment. By introducing the latest equipment every year, they are able to deliver higher quality products to their customers, while also improving the work efficiency and reducing the burden on their employees.

We will continue to contribute to these efforts by proposing and supporting products and services.

Kyoshin Co., Ltd.

所在地 〒574-0064 大阪府大東市御領3丁目12番57号

TEL 072-889-5788

URL https://www.f-kyo-shin.co.jp

Haraguchi Machinery Co., Ltd.

所在地 〒594-0074 大阪府和泉市小田町1-5-32

TEL 0725-41-1880

URL https://haraguchikk.co.jp