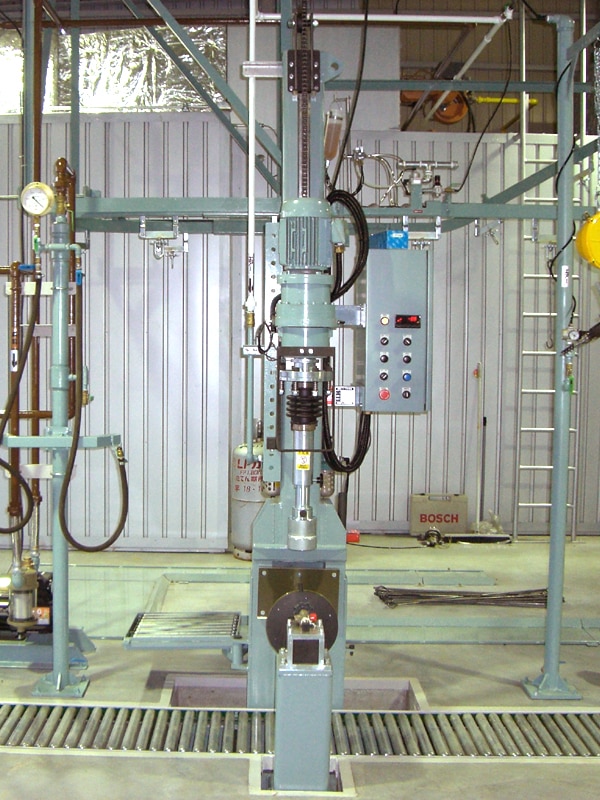

Maruei Co., Ltd. was considering renovating their testing center with the goal of creating a testing center that would attract people.

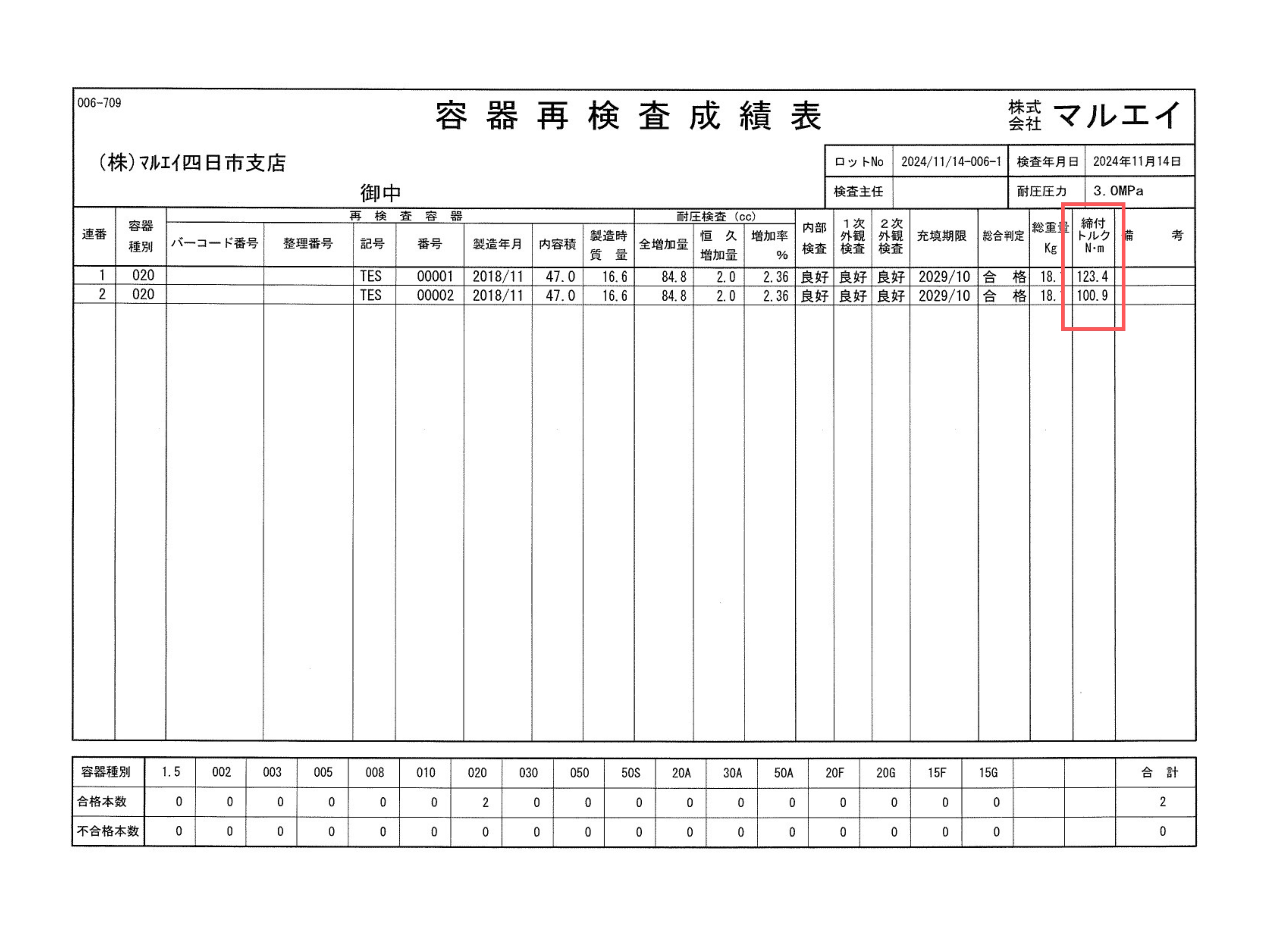

In particular, they had been struggling for many years with measures to prevent human error when removing and attaching valves. Previously, neck leak inspections were carried out based on checklists when cylinder were shipped from the inspection center and before filling at the filling stations (each of Maruei Co., Ltd.'s locations). However, there were limits to what could be done by humans, and Maruei Co., Ltd.'s policy was to solve the fundamental problem and completely eliminate neck leaks, thereby preventing accidents from occurring.

While considering an update,

The device physically stops when an error occurs.

No need for major renovations

Reduces the workload of workers

They said that these points were the deciding factors in their decision to use our valve removal machine. Furthermore, other companies' devices do not have the function to record tightening torque values in a performance report, which gave them hope that this would give them peace of mind.