Insulpin welding

Fast and strong

Supports reliable welding

Tenma metal working Ltd.

Representative Director Yasuhiro Miyata

CD stud welding machineinstallation example

Tenma metal working Ltd.

Representative Director Yasuhiro Miyata

CD stud welding machineinstallation example

Company name

Tenma metal working Ltd.

location

〒729-4101

2090 Hongo, Kono-cho, Miyoshi City, Hiroshima Prefecture

Number of employees

10 people

Business content

Can manufacturing and sheet metal processing

Introduction products

CD stud welding machine

URL

https://tenma-ltd.jp

the purpose

- Efficiently welds Insulpin

assignment

-It was necessary to work efficiently while ensuring strength.

-Manualwelding leaves weld marks and distortions, making post-processing time-consuming.

effect

- Almost no distortion or noticeable welding marks occur, so no post-processing is required

- There is no need to precisely adjust the current, allowing anyone to perform welding under stable conditions.

Click here for detailed specifications of CD stud welding machine

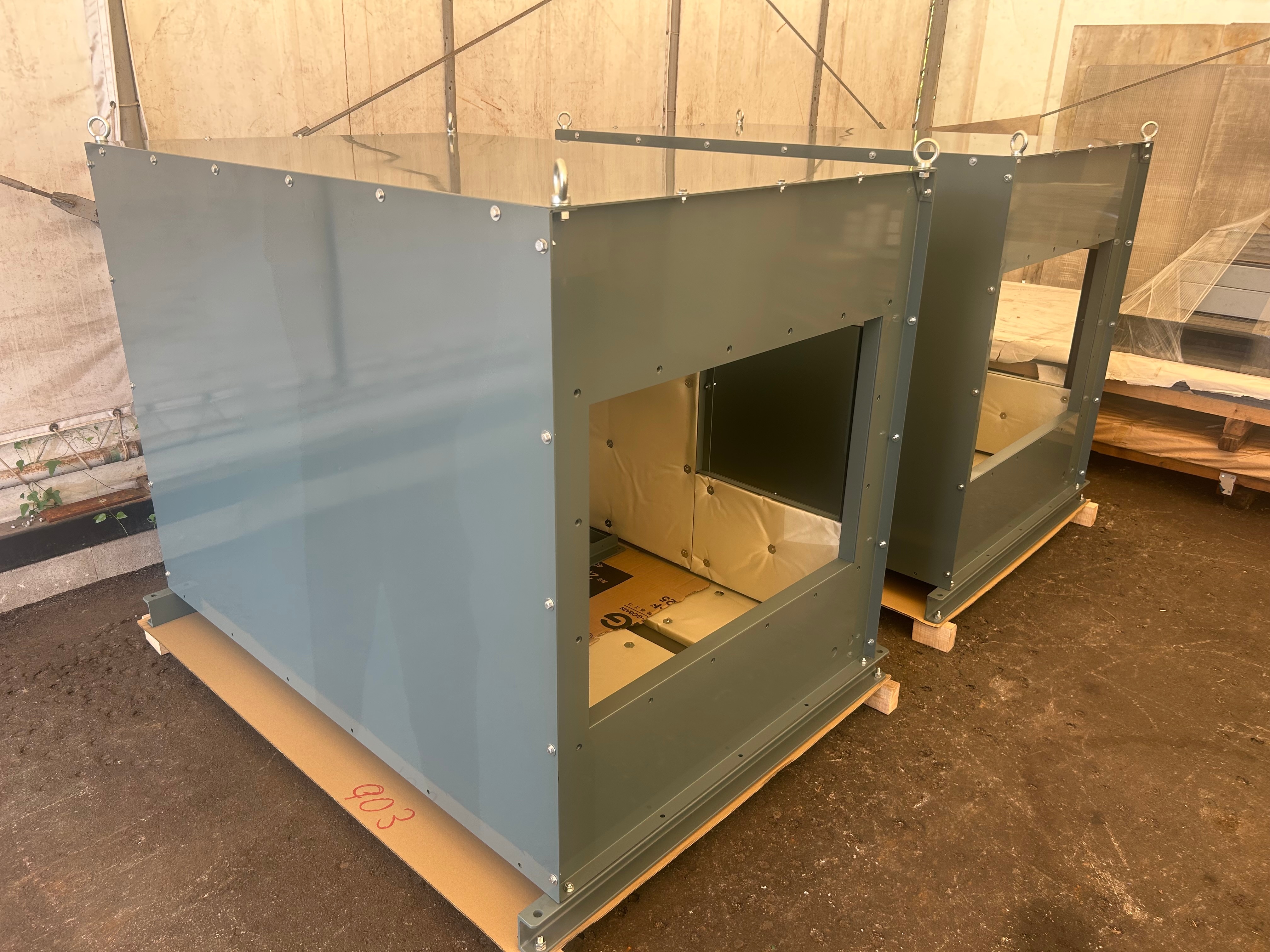

Inside the factory

Air conditioning fan housing

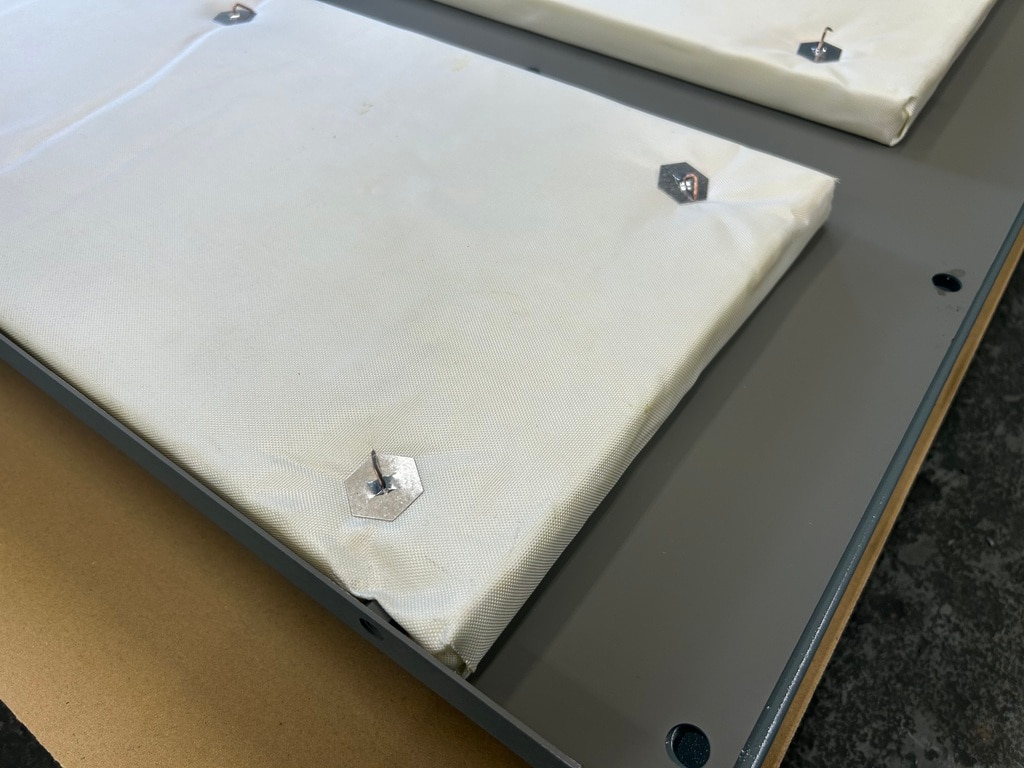

Our CD stud welding machine was introduced to weld insulpin. By changing the gun parts, this machine can weld not only bolts but also insulpin. Tenma metal working Ltd. mainlyTeral Co., Ltd.It is used to secure sound-absorbing material to air conditioning blowers made of aluminum.

Larger air conditioning blowers require as many as 200 pins to be welded per unit, and because they are subjected to great pressure during operation, high welding strength is required. Tenma metal working Works sometimes welds as many as 1,000 pins in a day, and our stud welding machine was highly rated as a device that can meet both the workload and the strength requirements.

The deciding factor in the introduction was the combination of "productivity that can stably handle large volumes of welding" and "welding strength that can withstand the pressure when the machine is operating."

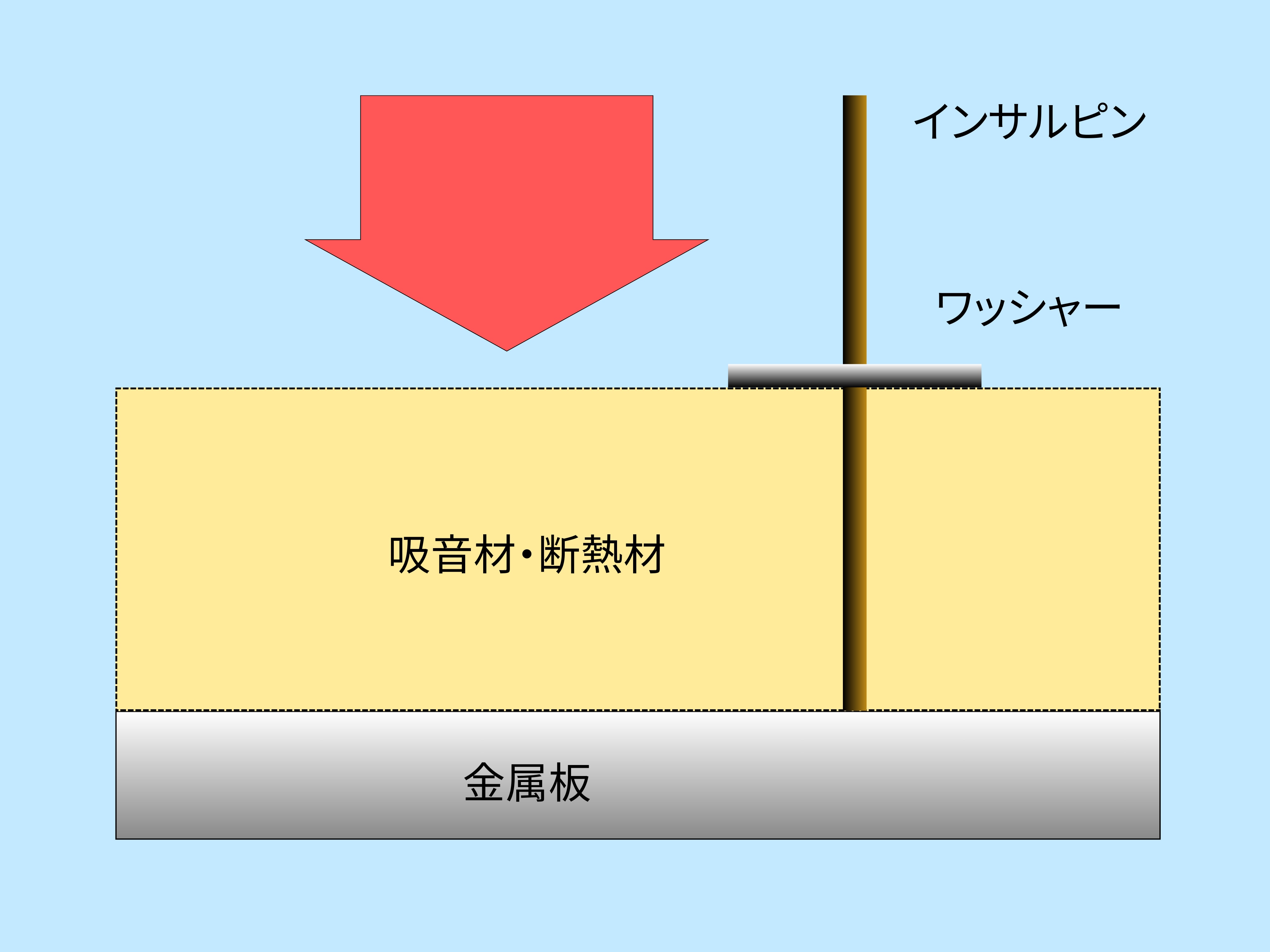

Insulpins are special pins used to secure sound-absorbing and heat-insulating materials to metal plates and other surfaces.

One end of the pin is stud welded directly to the base material, and then sound-absorbing and insulating material such as glass wool or rock wool is inserted on top and secured with a washer.

They are often used inside air conditioning fans and ducts, and are required to be able to securely hold sound-absorbing material while withstanding the vibrations and pressure caused by machine operation.

① Improved efficiency of finishing work

② Stable operability and welding quality

The first is the efficiency of finishing work. Manual welding inevitably leaves weld marks and distortions, which require a lot of time and effort to be spent on post-processing such as polishing and repair. Heat has a particularly large effect on thin plates, and neatening the finish after welding is a major burden. By introducing the stud welding machine, distortion and noticeable weld marks hardly occur, even with thin plates, and post-processing is no longer necessary. As a result, not only has the work process been shortened, but product quality has also stabilized, leading to greater efficiency on the entire site.

The second is ease of operation and stable welding quality. Our stud welding machines use digital control, and the machine automatically adjusts the optimum current to suit the base material. There is no need for the operator to fine-tune the current, and anyone can weld under stable conditions. On-site workers have praised the machine, saying, "I can work with peace of mind because I don't have to worry about settings and stable welding can be performed."

Click to enlarge image.

Tenma metal working Ltd. has always responded carefully to sudden requests, and this attitude has built a strong reputation for trust. While valuing this flexible response, they aim to create a more stable structure by expanding the range of products and work they handle, rather than relying solely on sudden work. They also want to be a presence that can help their partner companies when they are in trouble.

We will continue to make proposals and provide support to ensure that we can firmly support these efforts.

Tenma metal working Ltd.

所在地 〒729-4101 広島県三次市甲奴町本郷2090番地

TEL 0847-67-2505

URL https://tenma-ltd.jp