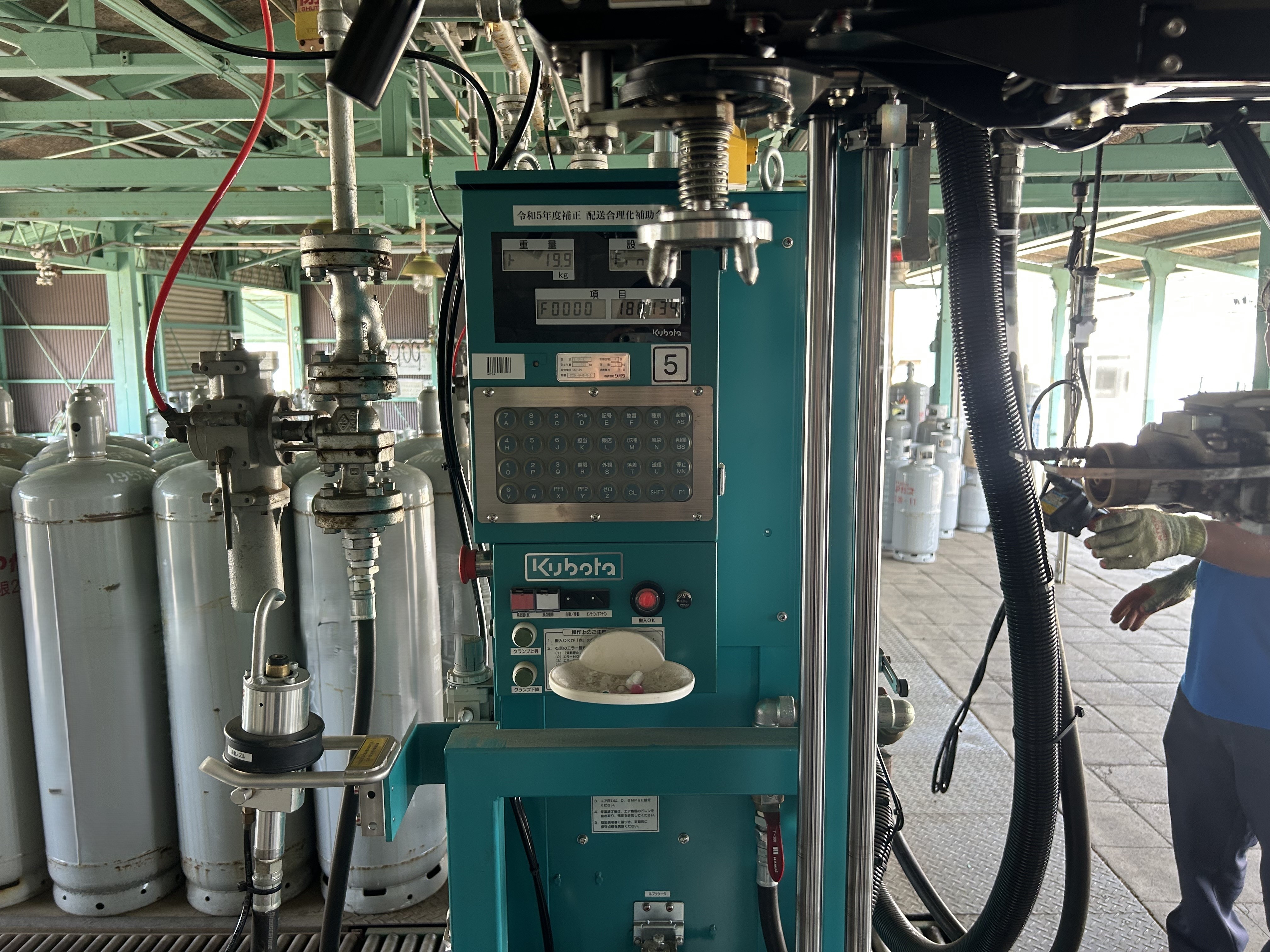

The reason for considering an update was the increasing number of breakdowns caused by the aging of filling machines made by other companies.

When a malfunction occurred, they would repair it in-house using the parts they had on hand, and if that didn't work, they would ask a maintenance company for help. However, there were times when the response was delayed and it caused problems for business, so they decided to upgrade.

When considering the product, they compared it with filling machines made by other companies, but chose our product because of its long-term reliability, extensive track record, and standardized system. In Fukui Prefecture, more than 70% of filling stations that have introduced electronic filling machines use UNIDACK filling machines, and they said that the track record of being the local choice gave them peace of mind.

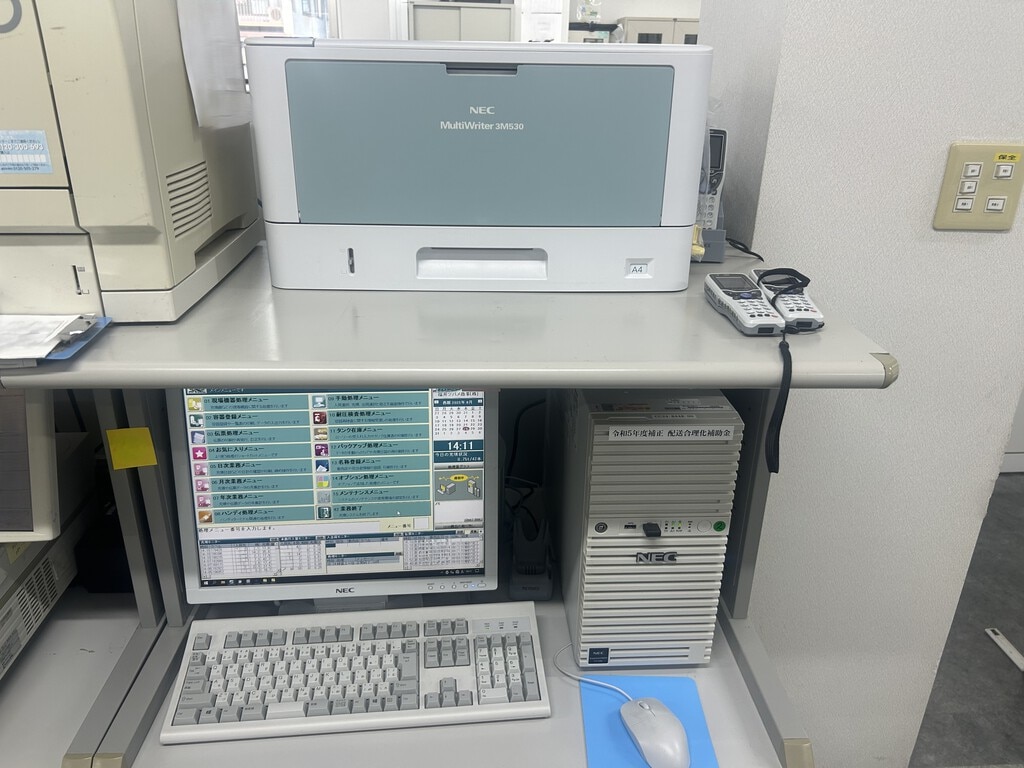

Furthermore, because the previous filling management system was operated through repeated customization, when an error occurred, there was the inconvenience that "no one knew how to fix it." UNIDACK's filling management system is packaged, so anyone can operate it easily, and remote support is also available in the event of an error. This aspect matched Fukui Tsubame Shoji Co., Ltd.'s desire to "standardize."