Explaining the cost-effectiveness of metal saw blade miter cutting cutting machines!

In recent years, various machines have been developed in the industrial field, and new technologies have been introduced to improve work efficiency.

Among these, there are several types of cutting machines, and in this article we will explain the differences between miter cutting cutting and straight cutting cutting metal saw blade saws, as well as their cost performance.

Click here for an article about metal saw blade

What is metal saw blade? Explanation of the material and blade shape!

Explanation of metal saw blade cost calculation! How much can you save per year?

Table of contents [hidden]

- 1.Whatis metal saw blade cutting?

- 2.Difference between miter cutting cutting straight cutting cutting metal saw blade

- 3.Advantages of metal saw blade saw miter cutting cutting machines

- 4.Specific cost examples of metal saw blade miter cutting cutting machines and straight cutting cutting machines

- 5.Sample of our miter cutting cutting machine

- 6.Summary_

What is metal saw blade cutting?

Introduction metal saw blade cutting is a cutting method that uses a circular blade (metal saw blade) with a special tooth shape used to cutting metal materials.

Unlike regular saws or band saws, metal saw blade have a rotating disk that can cutting metal efficiently.

The features of metal saw blade cutting are as follows:

・ High-speed and accurate cutting: metal saw blade rotate at high speeds and can cutting metal materials quickly. In addition, they are less likely to bend than band saws, so cutting precision is high and cutting to precise dimensions is possible.

・ Low heat loss: metal saw blade saw blades have little heat loss due to friction, resulting in less deformation and color change of metal, and a high-quality finish. In addition, no sparks or dust are generated.

- Less burrs and chipping: cutting metal saw blade produces smooth cutting surfaces, less burrs and chipping, and makes processing after cutting easier.

metal saw blade cutting is used in a variety of fields, including machining, construction, the automotive industry, and the aerospace industry.

>>Download the Daido Kogyo metal saw blade catalog

Difference between miter cutting cutting and straight cutting cutting metal saw blade

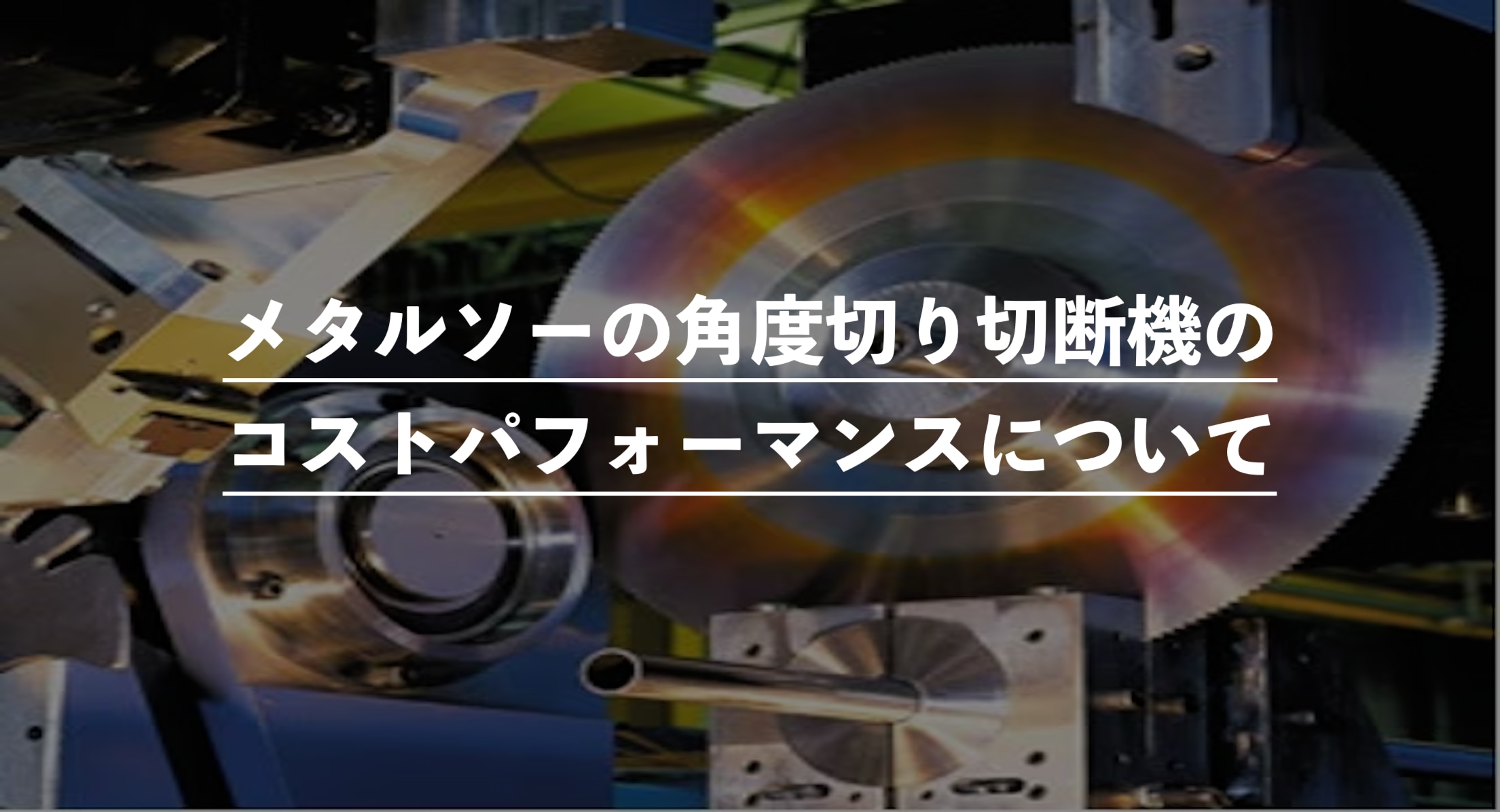

An miter cutting cutting, as the name suggests, is a machine that can cutting products at an angle. In contrast, a straight cutting-only cutting can only cutting products in a straight line.

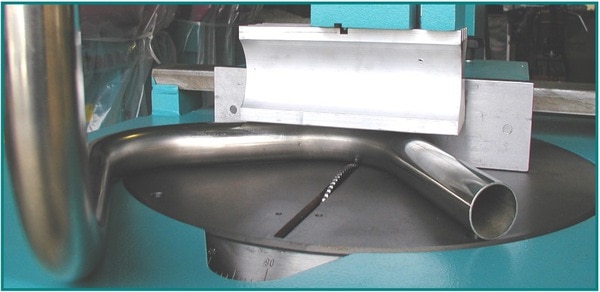

The diagram below shows an example cutting using our miter cutting cutting machine.

Advantages of metal saw blade saw miter cutting cutting machines

miter cutting cutting machines have a complex mechanical structure and are expensive, but they can also increase the unit price of the job.

This is because cutting at an angle can only be done with a special machine, so there is a special demand for it. Our miter cutting cutting can also be used for straight cutting cutting, so they are highly versatile and can be used for a wide range of jobs, so they can be used for a long time.

The image shows a Kaltenbach cutting machine, which we handle.

It is just like the extremely robust and highly precise German processing machines.

*Some users have been operating the equipment for over 30 years while undergoing repairs.

It can cut not only at angles but also straight.

In baseball, it would be easier to win if you are a versatile pitcher who can also throw curveballs, or if you are a fastball pitcher who can only throw fastballs, than a pitcher who can only throw normal fastballs.

>>Download the Daido Kogyo metal saw blade catalog

Specific cost examples for metal saw blade miter cutting cutting and straight cutting cutting

For example, if a straight cutting cutting machine costs 3 million yen, and an miter cutting cutting machine costs 6 million yen, it may seem expensive at first glance, but the tasks that can be performed with miter cutting cutting machine are more diverse and the unit price of the work is higher, so as a long-term investment, miter cutting cutting machine is more cost-effective.

Let's say you have a job to cut one piece straight to the exact dimensions. The processing fee is 100 yen per piece. (There are many competitors, so the competition is likely to be fierce.)

There was a job to cutting it at an angle on both sides. Since there are few places that can do this, the job will be 500 yen per piece.

*This is an easy-to-understand comparison based on processing fees only.

Suppose that the work takes twice as long as the time to straighten cutting the straightener, considering the angle labor.

If a straight cutting machine can do 100 cutting per hour, the profit per hour for each machine is as follows

<Calculation formula>

Straight cutting: 100 yen x 100 pieces = 10,000 yen

Angle cutting machine: 50 pieces per hour (half the number because the working time is doubled) x 500 yen = 25,000 yen

The difference in the initial investment cost for the machinery is the price of the angle cutting machine (6 million yen) minus the price of the cutting machine (3 million yen), or 3 million yen.

If you divide this difference by the difference between the profit of the angle cutting machine and the profit of the straight cutting machine, you can see how many units and time you need to do to make a profit compared to the straight cutting-only cutting.

<Calculation formula>

3 million yen ÷ (25,000 yen - 10,000 yen) = time

Working time = 2,00 hours

In other words, if you work 8 hours a day, the difference will be made up in 25 days, and you will then be in the black. Of course, straight cutting is also possible.

*This is just a trial calculation example, so we would appreciate it if you would take into consideration your company's cutting cost, added value, space saving of the machine, etc. when making your calculations.

Conversely, if you are looking for a machine that only cutting in straight lines, a machine that can cutting a large number of pieces per hour at high speed will be more cost-effective.

In that case, please use our high-performance metal saw blade.

>>Download the Daido Kogyo metal saw blade catalog

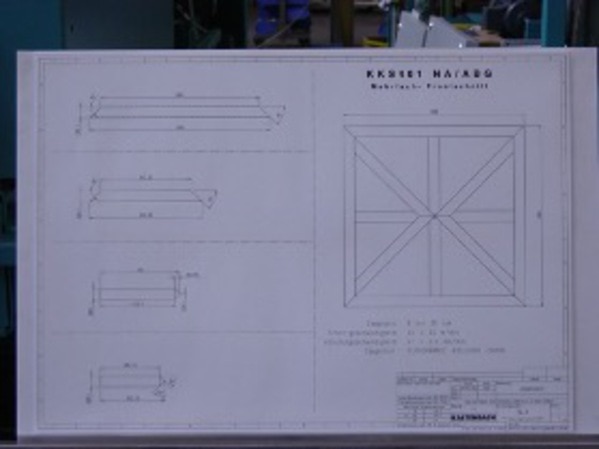

Processing sample of our miter cutting cutting machine

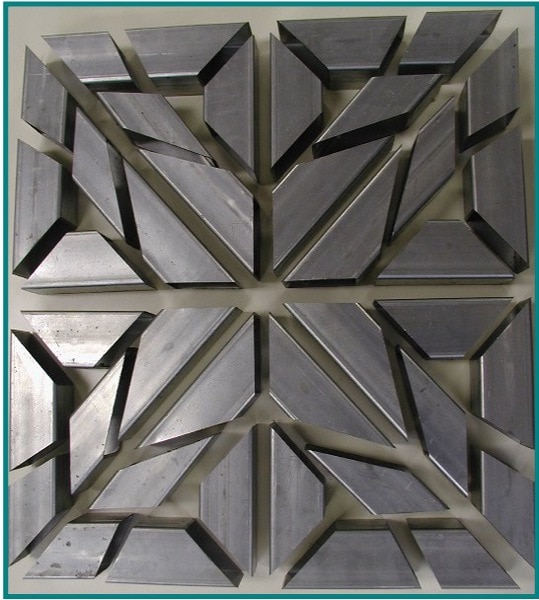

The photo shows a sample from Germany, but domestic sheet metal processing companies also have many successful results.

*We also handle deburring machines, bender, and welding machines, so we can offer you a package proposal.

This is unique to the Kaltenbach cutting machine, and has a proven track record in cutting the bends of bent pipes.

We have a proven track record of introducing our products to many muffler manufacturers and hydraulic piping manufacturers.

*When a pipe is bent with bender, there will inevitably be straight sections at both ends. To cutting these sections, it seems that a cutting machine unique to Kaltenbach, which presses down from above and has a blade that comes out from below, is convenient to use.

We also have users who use jigs to cutting pieces in three dimensions.

It's an image of two diagonals.

Kaltenbach cutting machines have very high angle precision and do not leave gaps during subsequent welding work, which is another reason for their popularity.

*Created using a Kaltenbach cutting machine

summary

In this article, we have explained the differences between miter cutting cutting and straight cutting cutting metal saw blade and their cost performance.

A versatile machine that can do just about anything can expand the scope of work and also set a higher unit price.

Of course, compared to a dedicated machine that only pursues one purpose, its capabilities may be lacking in some respects, but the problem with a dedicated machine is that it is less susceptible to changes in work (the investment is wasted) compared to a general-purpose machine. It has become.

First of all, if you are going to choose one machine, I think the reason why we recommend a cutting machine that can cut at angles will ultimately make a difference in cost performance.

At Daido Kogyo, our industrial machinery professionals will listen to your company's concerns and provide consulting support to solve your problems.

We will listen to your company's issues, such as aging machines and improving production efficiency, and propose machines that meet your needs.

You can see the list of metal saw blade products here.

Thank you for reading to the end.

You can download the catalog for free using the button below.

Please feel free to contact us here.