By simply setting the filling unit on cylinder, the entire process from opening the valve to filling, closing the valve, and removing the unit can now be carried out automatically. This allows workers to use the time saved during filling to organize cylinder or perform other tasks, improving the efficiency of the entire site.

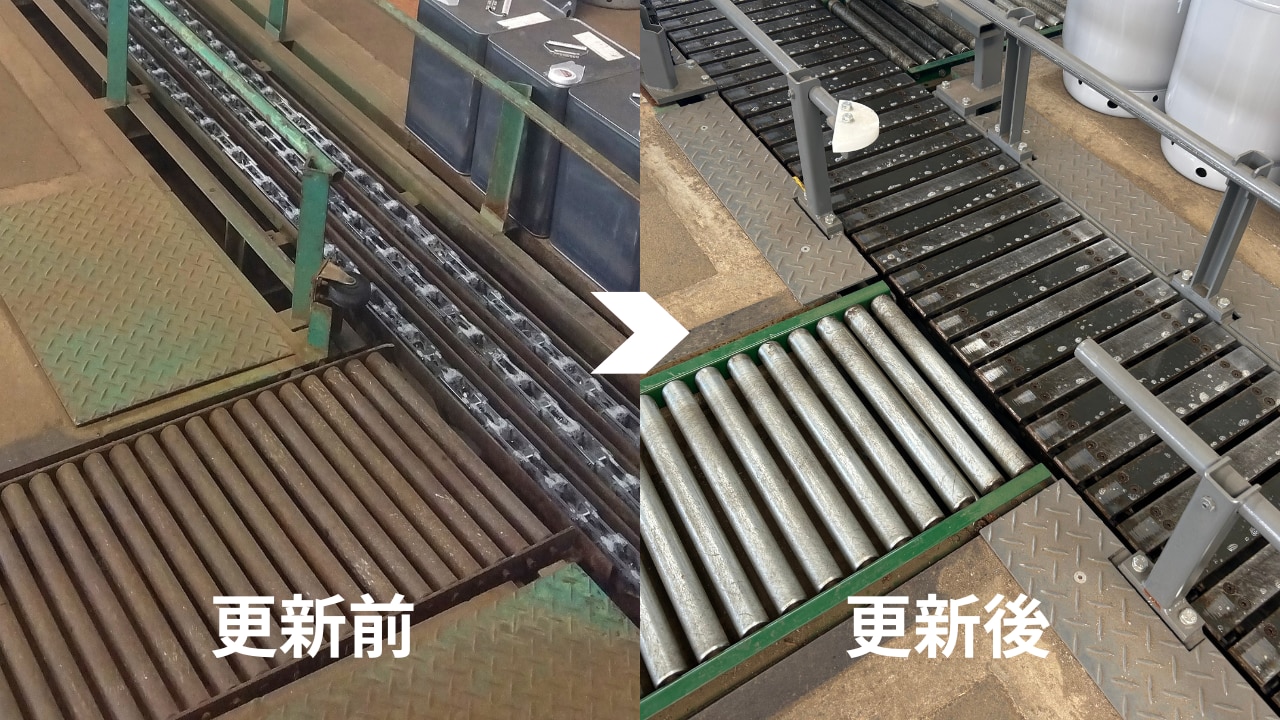

In addition, by changing the conveyor that transports cylinder from a three-chain conveyor to a slat conveyor, the difference in level with the free rollers was eliminated, allowing cylinder to be transported smoothly to the storage area.With the risk of cylinder tipping over reduced, filling work can now be carried out more safely and securely, according to the company.